Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In the realm of material handling, selecting the appropriate overhead crane is pivotal for ensuring efficiency and safety in various industrial applications. With numerous types available, it can be challenging to determine which overhead crane best suits specific operational needs. As industry expert Dr. Emily Carter emphasizes, “Understanding the distinct capabilities and configurations of different overhead crane types is essential for optimizing workplace productivity and worker safety.”

Overhead cranes are vital in a multitude of sectors, from manufacturing to construction, facilitating the movement of heavy materials with precision. Each overhead crane type is designed with unique features suited to various tasks, and this makes it imperative for businesses to analyze their operational requirements thoroughly.

As we delve deeper into the various types of overhead cranes available, it becomes evident that making an informed choice can lead to significant improvements in workflow and operational effectiveness. This guide aims to provide a comprehensive overview of the top overhead crane types, assisting you in making the best decision for your organizational needs.

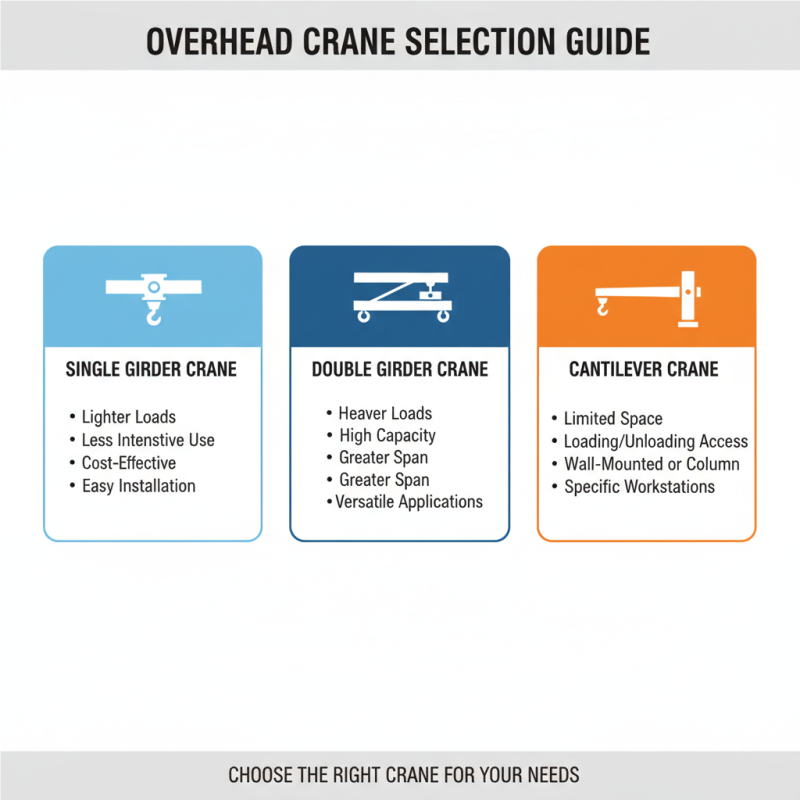

When selecting an overhead crane, it's essential to understand the various types available and their specific applications. The most common systems include single girder cranes, which are ideal for lighter loads and less intensive work environments, and double girder cranes, engineered for heavier lifting capacities and operational versatility. Another significant type is the cantilever crane, which provides excellent access for loading and unloading tasks in limited spaces.

Choosing the right crane not only depends on the weight capacity but also on the operational environment. For instance, overhead cranes used in manufacturing plants require high durability, while those utilized in warehouses may prioritize speed and maneuverability. When evaluating your options, consider the specific needs of your workspace, including width, height, and load handling frequency.

Tips for selection: Always consult with a professional to assess your facility’s specifications and workload demands. Additionally, evaluate future growth projections to ensure the crane can accommodate potential increases in capacity over time. Regular inspections and maintenance are crucial to ensure operational safety and efficiency, which can ultimately prolong the lifespan of your crane.

When deciding between bridge cranes and gantry cranes for industrial applications, understanding their fundamental differences is crucial. Bridge cranes typically consist of a horizontal beam that moves along two tracks, mounted on the building's columns. This design allows for efficient use of warehouse space and is particularly effective in facilities with high ceilings. According to industry reports, around 70% of facilities in manufacturing sectors prefer bridge cranes for their ability to handle heavy loads, often exceeding 100 tons, while maintaining precision and reliability.

On the other hand, gantry cranes offer versatility, as they can be used both indoors and outdoors. These cranes are typically supported by legs that move on wheels or tracks, allowing for mobility across large areas. They are ideal for operations that require lifting equipment in different locations, especially in construction and outdoor environments. Recent data indicates that gantry cranes can outperform traditional fixed cranes in terms of cost and flexibility, with installation and maintenance costs being significantly lower, making them an attractive option for many operations.

Choosing the right crane type ultimately depends on the specific needs of your operations, such as load weight, facility layout, and intended use. Organizations are increasingly leaning towards data-driven insights when making purchasing decisions, reflecting a trend in the industry towards optimizing lifting solutions that enhance productivity and reduce operational costs.

Jib cranes are versatile lifting solutions that offer significant advantages in various industrial settings. These cranes consist of a horizontal arm, or jib, that is mounted on a vertical post, allowing them to rotate and move loads with precision.

One of the key features of jib cranes is their ability to provide lifting capabilities in tight spaces where traditional overhead cranes may be impractical. This makes them particularly valuable in workshops, warehouses, and manufacturing facilities where maximizing space functionality is critical.

Another important benefit of jib cranes is their user-friendly operation. Many jib cranes are designed to be operated manually, which minimizes the requirement for complex training and enhances safety for operators. Additionally, their simple design means lower maintenance costs, as fewer moving parts reduce the likelihood of mechanical failures. Jib cranes can also be customized to accommodate various capacities and reach lengths, making them suitable for a wide range of lifting tasks.

Overall, their efficiency, adaptability, and ease of use make jib cranes a popular choice for many businesses looking to improve their material handling processes.

When selecting an overhead crane, several key factors must be considered to ensure it meets your operational needs efficiently. First, you should evaluate the load capacity required for your operations. Overhead cranes are available in various capacities, and understanding the maximum weight you'll be lifting is crucial. This includes not only the load itself but also any additional equipment or attachments that may be used alongside the crane.

Another important aspect to consider is the span of the crane. This refers to the distance between the supporting structures, such as beams or columns, and determines how far the crane can operate. It’s vital to accurately measure the work area to ensure the crane can cover the necessary space without limitations. Additionally, think about the environmental conditions where the crane will be used; factors such as temperature, humidity, and exposure to chemicals can affect the choice of materials and components in the crane's design.

Lastly, the frequency of use should be weighed—high-frequency operations may require more robust and durable cranes compared to those used intermittently. By focusing on these aspects, you can choose the right overhead crane tailored to your specific needs.

When selecting an overhead crane, understanding safety standards and regulatory compliance is crucial for ensuring both operational efficiency and worker safety. In the United States, the Occupational Safety and Health Administration (OSHA) provides strict regulations that employers must follow, which include guidelines on crane design, maintenance, and operational practices. According to a report by the Crane Safety Network, adhering to these OSHA regulations can significantly reduce workplace accidents, which remain a pivotal concern across various industries. In fact, industries that consistently comply with these standards report up to 50% fewer incidents related to crane operations.

Furthermore, the American National Standards Institute (ANSI) and the Crane Manufacturers Association of America (CMAA) set forth additional guidelines that further enhance safety measures. These standards detail requirements for crane inspections, testing protocols, and operator certification. A recent industry analysis highlighted that companies that implement comprehensive training and certification programs for their crane operators experience a marked improvement in workplace safety metrics, effectively fostering a culture of compliance and responsibility. As the industry continues to evolve, the integration of advanced technologies, such as load monitoring systems and automated safety features, has further supported compliance efforts, making it easier for organizations to meet and exceed regulatory expectations.