Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In the modern industrial landscape, selecting the right overhead crane is crucial for operational efficiency. According to recent data from the Material Handling Industry of America, overhead cranes enhance productivity by over 25% in heavy-duty applications. With various models available, businesses often struggle to determine which one best suits their specific needs.

Different environments require different cranes. For instance, a lightweight crane may suffice for small workshops, but larger manufacturing plants often need robust models to handle heavier loads. Experts suggest that companies evaluate their load capacity and workspace before investing. However, many fail to assess their needs thoroughly, leading to costly mistakes.

Understanding the various overhead crane models can significantly impact safety and productivity. Reports indicate that improper usage or model selection results in increased maintenance costs and downtime. Therefore, careful consideration is essential. Making an informed decision today can prevent future regrets and operational inefficiencies.

Overhead cranes are vital in various industries. They help lift heavy loads efficiently. These cranes come in different types, including bridge, gantry, and jib cranes. Each type has unique applications, allowing for versatility in handling materials. For instance, bridge cranes are common in manufacturing plants. They move across a track, providing excellent coverage.

Gantry cranes, on the other hand, are suitable for outdoor environments. They can lift containers and large equipment. Hospitals often use jib cranes for lifting medical supplies. However, choosing the right type for your business can be challenging. It involves considering load capacity, space, and safety regulations.

Understanding the specific needs of your operations is crucial. This knowledge helps in selecting the ideal crane type. Reflecting on past experiences with equipment can guide future decisions. Assessing the areas where performance lacks is also beneficial. The goal is to enhance operational efficiency while ensuring safety.

This chart represents the lifting capacity of various overhead crane models commonly used across industries. The data reflects the maximum load each model can handle, crucial for meeting specific operational demands.

Choosing the right overhead crane model for your business requires careful consideration. One of the key features is the load capacity. Understand the maximum weight your operations require. This will help you avoid selecting a model that can’t handle your demands. A crane that is too weak can lead to accidents. A model that is too strong may be unnecessarily expensive.

Another important factor is the span of the crane. Measure the area where the crane will operate. A wider span can enhance productivity by reaching more areas. However, a crane with a too wide span might require substantial investment. It's crucial to balance cost with function, especially for smaller operations. The height of the lift is also vital. Ensure the crane can reach all necessary points in your facility.

Additionally, consider the crane's control system. User-friendly controls can significantly impact efficiency. Some systems may feel outdated or difficult to operate. Training staff on complex systems can lead to delays. Don't overlook maintenance needs. Regular upkeep is essential for safety and functionality. Neglecting maintenance can lead to larger issues down the line. Each aspect matters; take the time to evaluate properly.

When selecting an overhead crane, performance metrics are crucial. Load capacity stands as a primary metric. Common models can handle 5 to 50 tons. However, choose according to your specific needs. For heavier tasks, look for cranes with a higher capacity.

Speed and control are also vital. Many models offer lifting speeds of 3 to 15 meters per minute. Smooth operation is essential to maintain safety. A crane that operates too quickly may compromise load stability.

Energy efficiency is another factor to consider. Studies show that efficient overhead cranes can save up to 30% on energy costs. Employers are increasingly focused on sustainability. They seek models that blend performance with environmental responsibility. Some models incorporate regenerative features. This can enhance their overall effectiveness, but the initial investment might be higher.

| Model | Load Capacity (tons) | Span (m) | Lift Height (m) | Speed (m/min) | Power Source | Applications |

|---|---|---|---|---|---|---|

| Model A | 10 | 10 | 6 | 15 | Electric | Manufacturing, Warehousing |

| Model B | 15 | 12 | 8 | 10 | Diesel | Construction, Heavy Fabrication |

| Model C | 20 | 15 | 10 | 20 | Electric | Shipping, Ports |

| Model D | 5 | 8 | 5 | 12 | Battery | Light Industrial |

| Model E | 12 | 9 | 7 | 18 | Electric | Automotive, Assembly |

| Model F | 25 | 18 | 12 | 8 | Electric | Steel Processing, Manufacturing |

| Model G | 30 | 20 | 15 | 5 | Hydraulic | Aerospace, Heavy Machinery |

| Model H | 8 | 10 | 6 | 10 | Electric | General Manufacturing |

| Model I | 10 | 12 | 9 | 14 | Diesel | Material Handling |

| Model J | 22 | 30 | 20 | 25 | Electric | Shipbuilding |

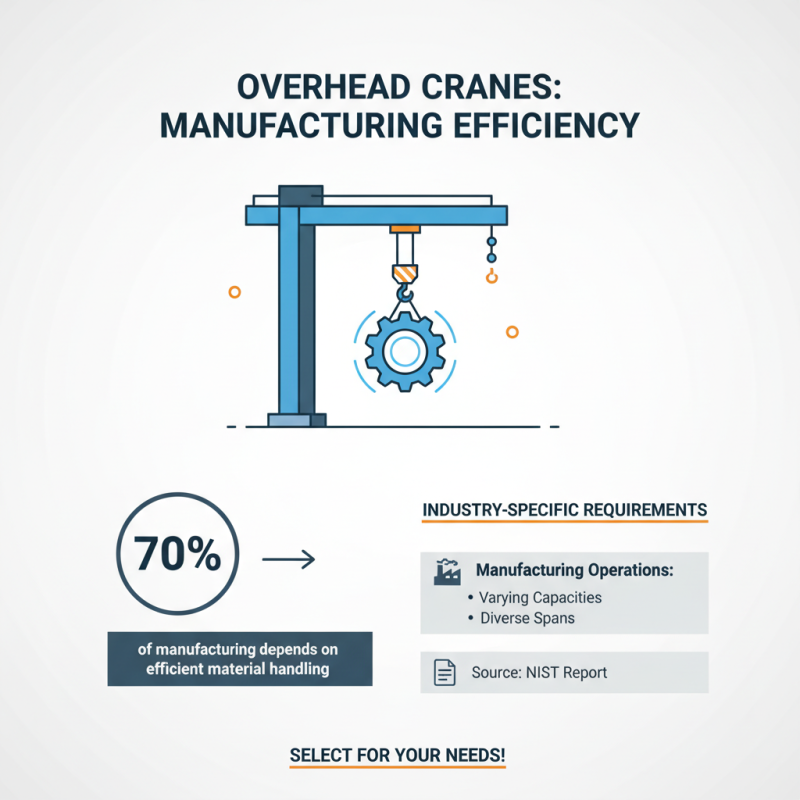

When selecting an overhead crane, industry-specific requirements are crucial. Manufacturing operations might require various capacities and spans. According to a recent report by the National Institute of Standards and Technology, nearly 70% of manufacturing processes depend on efficient material handling systems. Overhead cranes provide that efficiency, allowing for seamless movement of heavy loads.

Different sectors have unique needs. For example, the automotive industry often requires cranes with high lifting capacities. In contrast, food processing may prioritize washdown capabilities for cleanliness. A 2022 market analysis indicates that the Asia-Pacific region is expected to dominate with a 5.8% CAGR due to rising automation. Yet, many facilities still rely on outdated models lacking modern safety features.

Personalizing crane specifications is vital. Operators must consider factors, like the type of materials handled and load weights. A recent survey found that 40% of businesses feel their crane system does not align with production demands. This misalignment can lead to inefficiencies. Implementing the right overhead crane model could enhance operational workflow, yet ensuring proper training remains a challenge for many manufacturers.

When operating overhead cranes, safety is paramount. This equipment handles heavy loads, often in busy environments. Complying with safety standards can prevent accidents. Training staff members on proper usage is essential. Regular inspections should also be part of daily operations. Operators must understand weight limits. Failing to do so can have severe consequences.

Regulatory compliance varies by region. It's crucial to be aware of local laws. Ignoring these regulations can lead to penalties. Some businesses overlook necessary certifications. This negligence can jeopardize safety. The cost of compliance might seem high initially. However, investing in safety pays off over time. It's about prioritizing worker well-being.

Safety protocols should evolve as technology advances. New developments make cranes more efficient but can introduce risks. Each company must assess its unique needs regularly. Reflecting on past incidents can help improve safety measures. True compliance requires ongoing effort and attention.