Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In today’s fast-paced industrial environment, the efficiency of material handling systems is paramount. One of the most transformative tools in this realm is the Ceiling Crane, which streamlines the movement of heavy loads while enhancing workplace safety. According to industry expert Dr. John Anderson, a leading figure in material handling technologies, “The implementation of a Ceiling Crane can significantly reduce the physical strain on workers while improving operational efficiency.” This statement encapsulates the growing recognition of Ceiling Cranes as vital components in modern facilities where heavy lifting is routine.

As operations evolve, the benefits of leveraging Ceiling Cranes become clear. From reducing labor costs to minimizing the risk of workplace injuries, these systems not only optimize workflow but also contribute to a more productive environment. In addition, Ceiling Cranes are designed to be adaptable and scalable, making them suitable for a variety of applications, from manufacturing to warehousing. By integrating this innovative equipment into material handling processes, companies can unlock a new level of operational efficiency, ensuring a safer and more effective approach to moving goods.

Ceiling cranes have become an invaluable asset in material handling operations across various industries, significantly enhancing efficiency and safety. One of the primary advantages of ceiling cranes is their ability to maximize vertical space, allowing for seamless movement of heavy materials in confined areas. According to a report by the Occupational Safety and Health Administration (OSHA), companies that employ overhead lifting systems can reduce workplace injuries by up to 50%, showcasing how effective material handling solutions contribute not only to productivity but also to employee safety.

Moreover, ceiling cranes facilitate streamlined workflows by reducing the need for manual handling of heavy loads. The American Society of Mechanical Engineers (ASME) highlights that businesses utilizing ceiling cranes can improve operational efficiency by up to 30%. This is particularly crucial in sectors like manufacturing and warehousing, where the safe and quick movement of materials directly correlates with overall productivity. The reduction of human labor involved in lifting and moving heavy items minimizes fatigue, thereby lowering the risk of injuries and increasing employee morale. By integrating ceiling cranes into material handling operations, organizations can achieve a more efficient, safe, and productive work environment.

Ceiling cranes are becoming increasingly popular in industrial settings due to their ability to enhance space utilization significantly. By positioning overhead, these cranes free up valuable floor space that can be used for other operations. Unlike traditional floor-mounted equipment, ceiling cranes don't obstruct pathways, allowing for smoother movement of personnel and materials within the workspace. This efficient use of vertical space makes it particularly beneficial in facilities where every square foot counts, such as warehouses, manufacturing plants, and distribution centers.

Moreover, improved space utilization with ceiling cranes leads to better workflow and productivity. By streamlining material handling processes, ceiling cranes allow for quicker loading and unloading of goods, reducing the time and effort required to transport materials across the facility. Workers can easily access materials stored at different heights without the need for bulky equipment that takes up additional floor space. This optimization not only enhances the efficiency of operations but also creates a safer working environment by minimizing congestion and the risk of accidents, ultimately leading to a more organized and productive workplace.

Ceiling cranes play a crucial role in enhancing safety measures within industrial environments. By utilizing overhead space for material handling, these cranes minimize the risk of accidents often associated with ground-based equipment. Workers are less likely to encounter hazardous situations when heavy loads are lifted above head, eliminating obstructions on the factory floor that can result in tripping or collisions. Moreover, ceiling cranes enable more efficient spatial organization, allowing for clear pathways and better overall traffic flow within the workspace.

Additionally, ceiling cranes are designed with built-in safety features such as automatic shut-off systems and overload protection, which help prevent potential injuries and equipment damage. Operators can manage heavy materials from a safe distance, reducing physical strain and the likelihood of personal injury. The ergonomic advantages of using ceiling cranes promote a safer working environment, aligning with best practices in workplace safety and helping to cultivate a culture of care and precaution among employees. With increased training and proper adherence to safety protocols, ceiling cranes not only enhance operational efficiency but also significantly contribute to a safer workplace atmosphere.

| Benefit | Description | Impact on Safety |

|---|---|---|

| 1. Reduced Manual Labor | Ceiling cranes minimize the need for manual lifting, reducing strain on workers. | Decreases risk of injuries associated with heavy lifting. |

| 2. Increased Efficiency | They streamline the material handling process, allowing for faster operations. | Minimizes the time spent on transporting materials, reducing potential hazards. |

| 3. Enhanced Precision | Ceiling cranes allow for precise placement of heavy materials. | Improves safety by ensuring materials are placed correctly, avoiding accidents. |

| 4. Improved Workflow | Facilitates better logistics and material movement within workflows. | Reduces congestion and potential hazards on the shop floor. |

| 5. Versatility | Can be used for a variety of materials and loads, increasing operational flexibility. | Helps in applying effective safety measures across different tasks. |

| 6. Space Optimization | Allows for overhead storage, utilizing vertical space effectively. | Minimizes the tripping hazards by keeping pathways clear. |

| 7. Enhanced Safety Features | Often include safety devices like emergency stop buttons and limit switches. | Directly contributes to the reduction of accident risks. |

| 8. Lower Operating Costs | Reduced labor costs and increased efficiency lead to lower overhead. | Less reliance on manual labor decreases injury-related expenses. |

| 9. Flexibility in Installation | Can be customized and installed in various building layouts. | Promotes safety in diverse working environments and set ups. |

| 10. Durability | Designed to withstand heavy use, providing longevity and reliability. | Long-term use without failure reduces safety risks. |

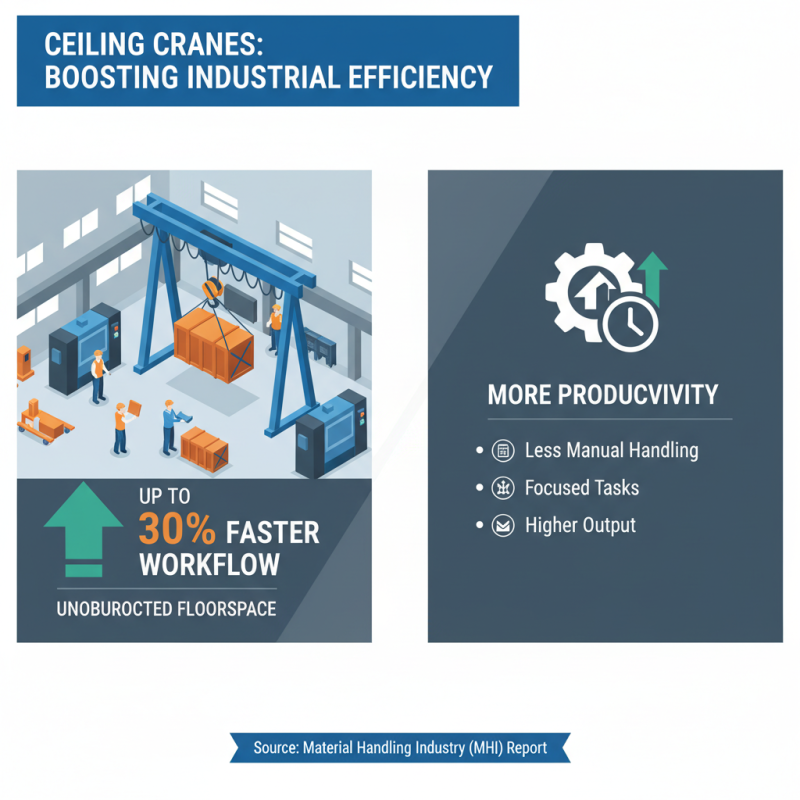

The implementation of ceiling cranes in industrial settings significantly enhances efficiency and productivity in material handling. According to a report by the Material Handling Industry (MHI), companies that utilize overhead cranes and hoists can increase workflow efficiency by up to 30%. This is largely due to the unobstructed floor space that ceiling cranes provide, allowing for smoother and faster movement of materials across the workspace. By minimizing the time spent on manual handling and transport, workers can focus on more critical tasks, leading to a higher output rate for the organization.

Furthermore, ceiling cranes reduce the potential for workplace injuries associated with manual lifting. The Occupational Safety and Health Administration (OSHA) estimates that ergonomic-related issues cost businesses about $15 to $20 billion annually in lost productivity and medical expenses. By automating the lifting and moving process, ceiling cranes reduce the likelihood of injuries, enabling employees to work with greater safety and efficiency. This not only boosts workers' morale but also enhances overall organizational productivity, as a healthier workforce contributes to a more effective production environment.

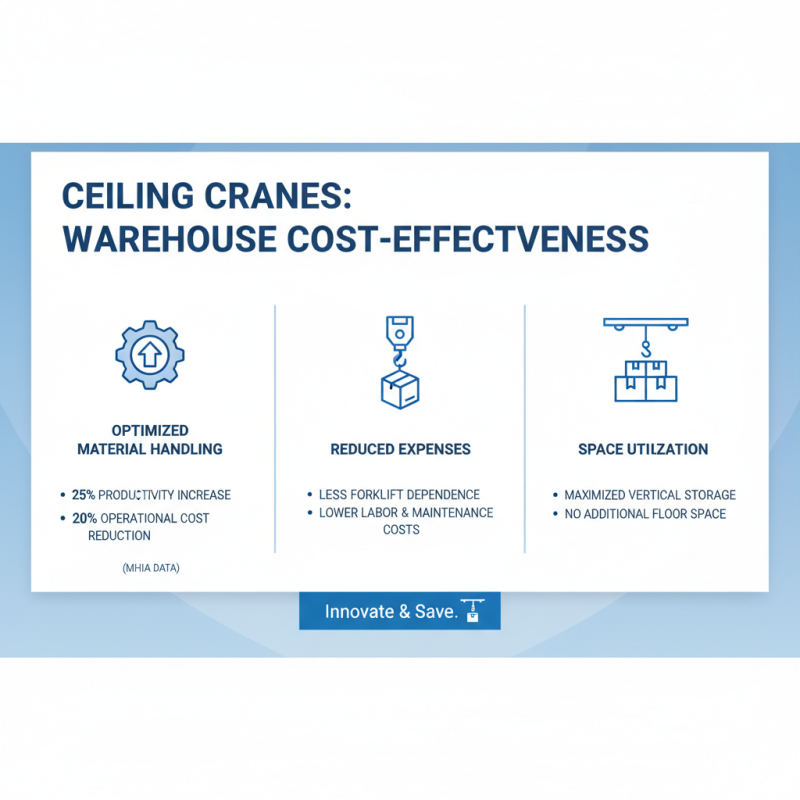

Implementing ceiling cranes in warehousing operations can significantly enhance cost-effectiveness by optimizing material handling processes. According to the Material Handling Industry of America (MHIA), efficient material handling systems can increase productivity by 25% and reduce operational costs by nearly 20%. Ceiling cranes reduce the need for forklifts and manual labor for heavy lifting, which translates into lower labor costs and decreased equipment maintenance expenses. By utilizing vertical space, these cranes enable warehouses to store more materials without requiring additional floor space, further enhancing cost efficiency.

Moreover, a report from the Occupational Safety and Health Administration (OSHA) highlights that using cranes for heavy lifting reduces workplace injuries, which can lead to substantial financial savings related to workers' compensation claims and lost labor hours. The implementation of ceiling cranes not only minimizes the risk of injury but also enables a more streamlined workflow, allowing employees to focus on other critical tasks. With an initial investment in ceiling crane systems, the long-term savings on labor and safety improvements can lead to a positive return on investment, making ceiling cranes a financially sound choice for modern warehousing environments.