Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

Eot Cranes are essential in modern industrial settings. Their unique design and functionality offer numerous advantages. Many industries rely on these cranes for efficiency and safety.

One major benefit of Eot Cranes is their ability to lift heavy loads. This capability enhances productivity in factories and warehouses. Operators can move materials quickly, reducing downtime. Moreover, their precision in lifting decreases the risk of accidents.

Another significant aspect is their space-saving design. Eot Cranes are often installed on elevated tracks. This feature allows for better utilization of floor space in busy environments. However, it’s crucial to consider maintenance needs. Regular checks ensure that these cranes operate safely and effectively. Overall, understanding the benefits of Eot Cranes can lead to more informed operational decisions.

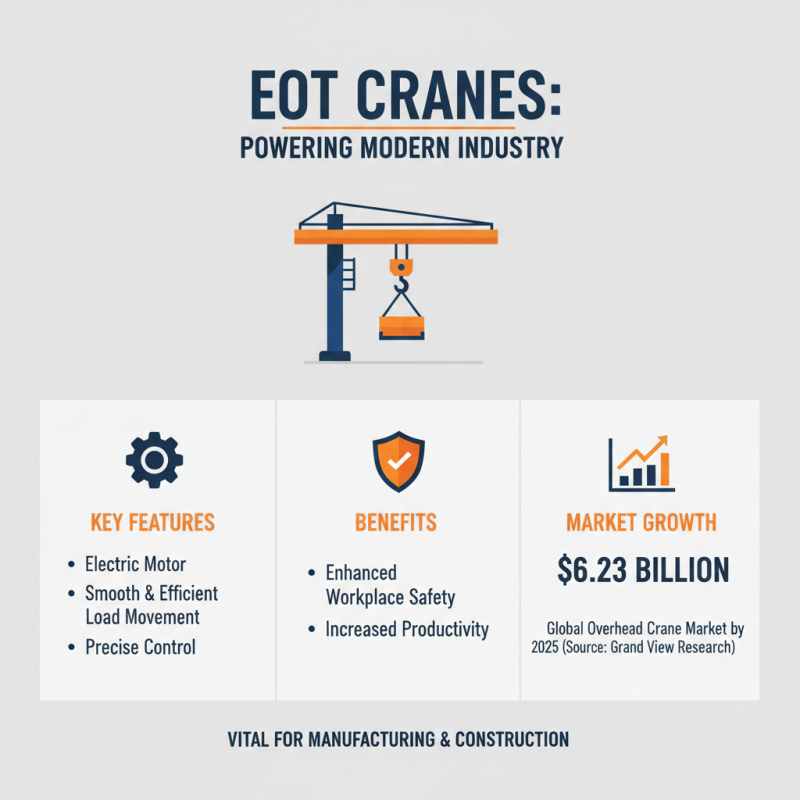

Electric Overhead Traveling (EOT) cranes are vital in modern manufacturing and construction. These cranes feature an electric motor to move loads smoothly and efficiently. Their design allows for precise control, enhancing workplace safety and productivity. According to a report by Grand View Research, the global overhead crane market is expected to reach $6.23 billion by 2025. This highlights their growing importance in various industries.

EOT cranes are known for their excellent lifting capacity. Some models can handle loads exceeding 100 tons. This capability is crucial for heavy industries such as steel and shipbuilding. Their compact design allows for utilization of vertical space, optimizing warehouses and factories. However, their installation and maintenance can be complex, requiring skilled professionals.

Energy efficiency stands as another key benefit. EOT cranes often use less energy than traditional lifting equipment. This can lead to cost savings over time. However, it's essential to consider the environmental impact of electricity sources used. Reports suggest that switching to renewable energy can further reduce the carbon footprint of crane operations. Striking a balance between efficiency and sustainability is an ongoing challenge for industries.

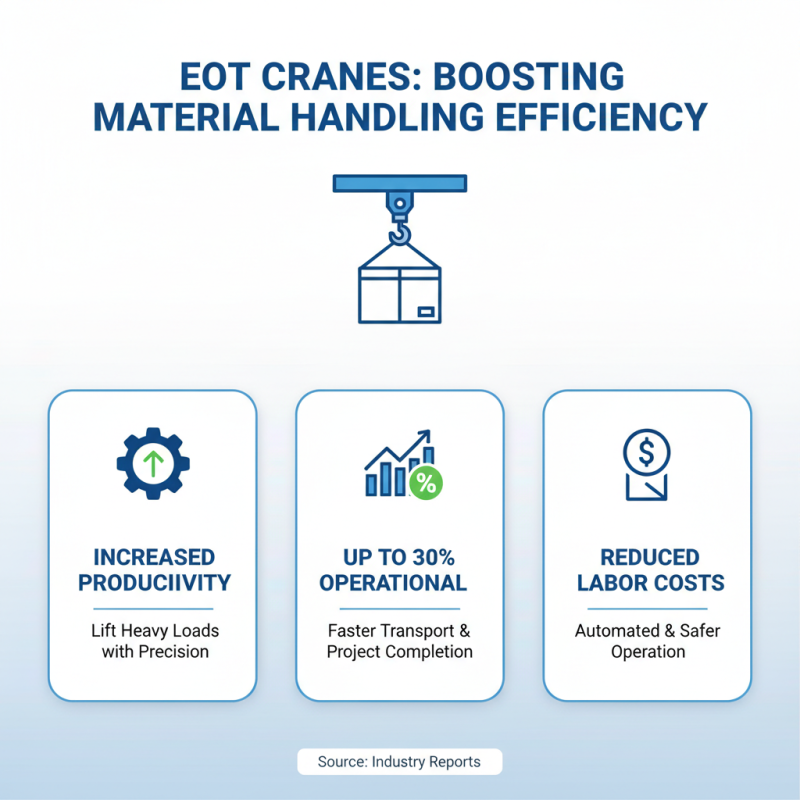

When it comes to material handling, efficiency is key. EOT (Electric Overhead Traveling) cranes significantly enhance productivity in warehouses and factories. These cranes can lift heavy loads with precision, reducing the time needed for transport. According to industry reports, companies using EOT cranes can increase operational efficiency by up to 30%. This boost in efficiency often translates into reduced labor costs and faster project completion.

Tips: Regular maintenance of EOT cranes is vital. Neglect can lead to downtime and increased costs. Always conduct routine inspections to ensure optimal performance.

Automation plays a critical role in maximizing crane benefits. Modern EOT cranes can integrate with intelligent systems, creating a streamlined workflow. Resolution of bottlenecks becomes easier when advanced controls are in place. However, it's essential to train operators thoroughly. A lack of training can lead to errors, negating the efficiency EOT cranes provide.

Tips: Offer continuous training sessions. This ensures operators stay updated on best practices. A well-trained staff is crucial for maintaining high efficiency levels.

EOT cranes are essential in industrial settings, primarily due to their safety features. Data from industry reports indicate that around 47% of workplace accidents occur during lifting operations. Thus, safety features in EOT cranes can significantly mitigate these risks.

One key safety feature is the overload protection system. This ensures that the crane does not lift beyond its capacity. Inadequate load calculations can lead to catastrophic failures. Another critical element is the emergency stop button, which allows operators to halt operations instantly in emergencies. This feature provides an added layer of safety, yet it requires proper training and awareness.

Moreover, regular maintenance and inspections are crucial. According to a study from the Occupational Safety and Health Administration (OSHA), 29% of crane-related accidents arise from poorly maintained equipment. Even the most advanced safety devices can fail if the crane has not been inspected properly. Personnel must be educated on safety protocols. This ensures that they understand the risks involved. Safety measures will only be effective if everyone is committed to following them.

EOT cranes are known for their cost-effectiveness in various industries. A recent industry report indicated that companies using EOT cranes can save up to 30% in operational costs. This is primarily due to their high efficiency and low energy consumption. They are designed to lift heavy loads with minimal power, which enhances overall productivity.

Maintenance benefits are equally significant. Regular maintenance can extend the lifespan of EOT cranes, which often translates to lower replacement costs. Data shows that scheduled maintenance can reduce breakdown incidents by 40%. This proactive approach prevents costly downtimes, ensuring continuous operations. However, some companies still overlook regular checks, leading to unexpected failures and financial losses.

Efficiency in operations is also tied to employee safety. Properly maintained cranes reduce accidents, which can be costly both in financial terms and in human resources. Yet, workers sometimes underestimate the importance of safety protocols. This gap can lead to unfortunate incidents, undermining the entire cost-effectiveness argument. Balancing maintenance and operational needs is crucial for maximizing the benefits of EOT cranes.

This bar chart illustrates the top benefits of EOT cranes, emphasizing cost-effectiveness and maintenance advantages. Each benefit is compared based on its perceived value by industry professionals.

EOT cranes offer remarkable versatility and customization options. These cranes can handle various tasks across different industries. From heavy lifting in manufacturing to precise movements in construction, their adaptability stands out. Users can select from various lifting capacities, boom lengths, and configurations to fit their specific requirements.

Customization is key. Users can integrate advanced technology like automated controls and safety features. Adapting the crane system ensures it meets the unique challenges of each project effectively. However, this customization can sometimes lead to complexity, making implementation challenging. It’s vital to balance between advanced features and ease of use.

Versatility also extends to their installation requirements. EOT cranes can be adapted for different space constraints. Yet, not every setup is flawless. Poor planning might lead to inefficiencies. Thus, reviewing all angles during the configuration process is essential. Each project is unique, and understanding these nuances can enhance performance.

| Benefit | Description | Versatility | Customization Options |

|---|---|---|---|

| Increased Efficiency | EOT cranes can significantly reduce the time required for lifting and moving materials, enhancing overall operational efficiency. | Can be used in various industries including manufacturing, construction, and warehousing. | Options for load capacity, span length, and control systems can be tailored to specific needs. |

| Space-saving Design | EOT cranes operate overhead, freeing up floor space for other activities or storage. | Suitable for facilities with limited ground space. | Can be designed to fit within existing structures without major modifications. |

| Enhanced Safety Features | Equipped with safety mechanisms such as emergency stops and limit switches to prevent accidents. | Adaptable for use in hazardous environments with specific safety standards. | Customization for additional safety equipment like anti-collision systems. |

| Reduced Labor Costs | Automating lifting tasks reduces the need for manual labor, leading to cost savings. | Utilizable in multiple applications across various sectors. | Customizable to accommodate specific handling requirements for various materials. |

| Durability and Longevity | Designed to withstand heavy loads and harsh conditions, resulting in a long service life. | Versatile enough to handle diverse lifting needs across different operational environments. | Customization options for materials and components to enhance longevity in specific applications. |