Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

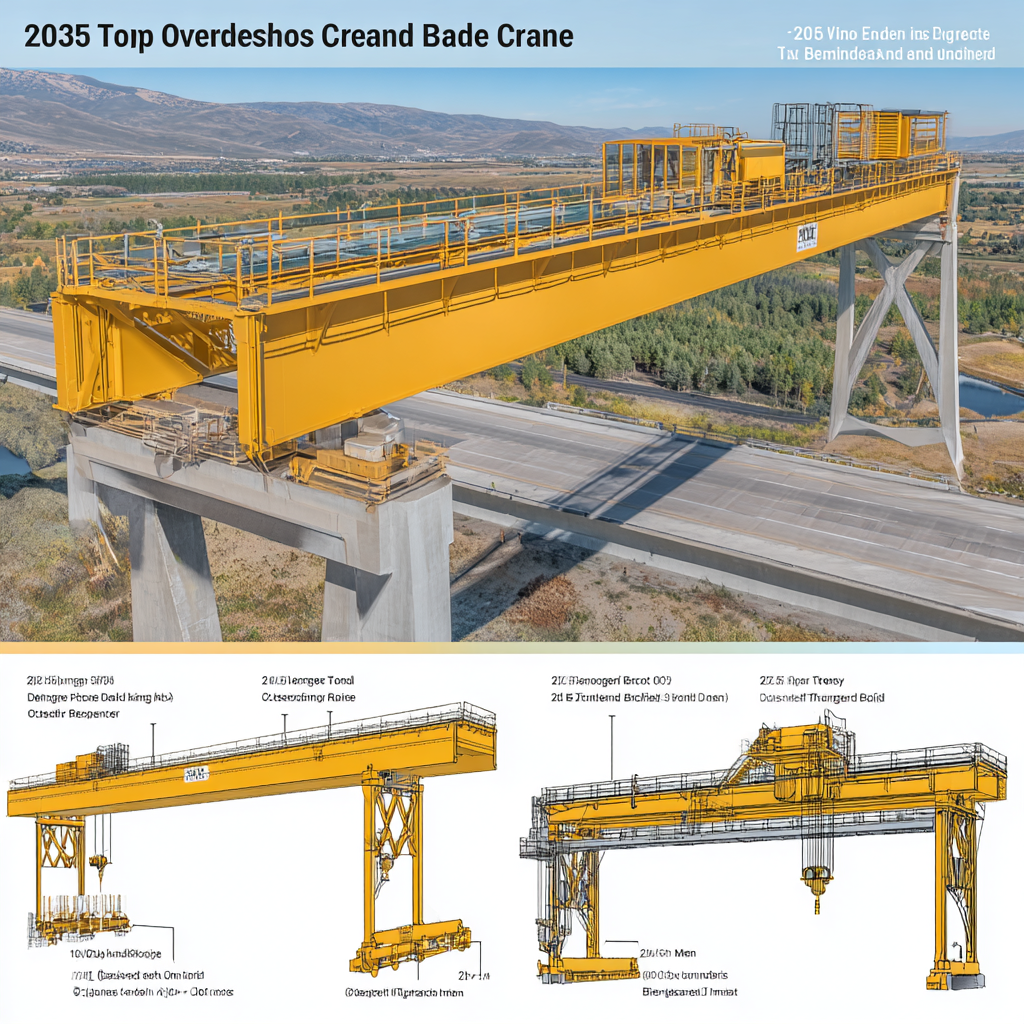

The overhead bridge crane industry plays a pivotal role in modern manufacturing and construction sectors, facilitating the safe and efficient movement of heavy loads. According to the latest report by the Global Cranes Market Research Institute, the global overhead bridge crane market is expected to reach $4.5 billion by 2025, with an annual growth rate of 5.8%. This growth is driven by increased automation and the need for effective material handling solutions in various industries.

Experts emphasize the importance of understanding the different types of overhead bridge cranes when making purchasing decisions. As noted by Dr. James Hartfield, a leading expert in industrial lifting solutions, "Investing in the right overhead bridge crane not only enhances operational efficiency but also significantly reduces workplace hazards." This statement underlines the necessity for buyers to comprehend the specifications, capacities, and features of various crane models, ensuring they select the most suitable equipment for their particular applications.

In this essential guide for buyers, we will explore the top 10 overhead bridge cranes of 2025, providing critical insights and recommendations to help you navigate the selection process. From function and design to key performance metrics, this guide aims to equip you with the knowledge needed to make informed decisions in the dynamic world of overhead bridge cranes.

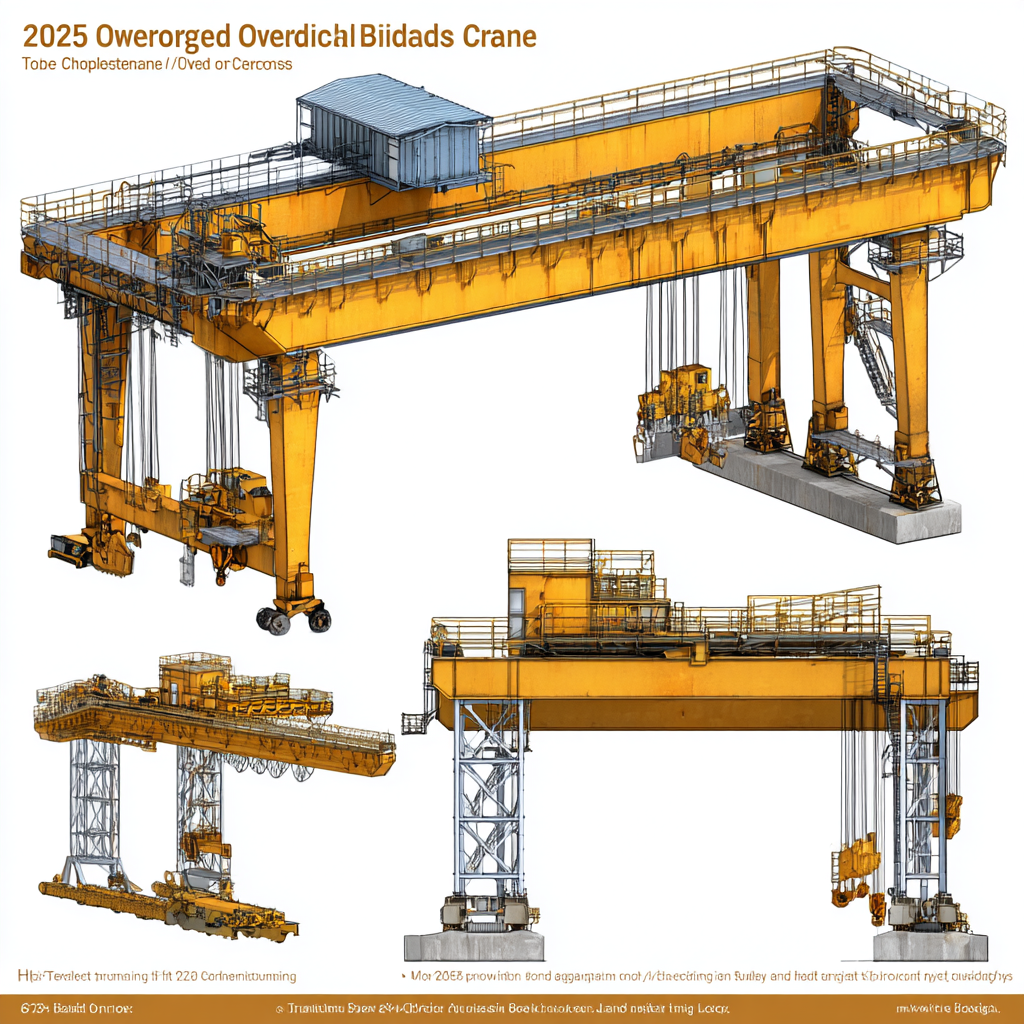

When purchasing overhead bridge cranes, buyers should prioritize several key features to ensure optimal performance and safety. First and foremost, load capacity is critical. Determine the maximum weight the crane will be required to lift and select a model that meets or exceeds this requirement. Additionally, consider the span and height of the lift. These factors will affect how the crane can be utilized within your facility, impacting efficiency and accessibility.

Another essential feature to contemplate is the type of drive system. Overhead bridge cranes can be equipped with manual, electric, or hydraulic systems. Electric systems are often favored for their precision and ease of operation, while hydraulic cranes may offer better performance in heavy-duty scenarios. Furthermore, the design of the crane should allow for easy maintenance; look for models with accessible components to reduce downtime and ensure longevity. Safety features, such as overload protection, emergency stop buttons, and safety locks, should also be part of your assessment to promote a secure working environment.

When considering an overhead bridge crane for your facility, understanding the leading brands of 2025 is essential for making an informed purchase. Major players like Konecranes, Demag, and Gorbel continue to dominate the market, each offering unique strengths in design, load capacity, and technology. Konecranes stands out with its focus on innovative automation solutions, enhancing operational efficiency. Demag, known for its robust build quality, is favored in heavy-duty applications, while Gorbel's flexibility in customizations caters to specialized needs.

**Tips:** Before making a decision, assess your specific lifting requirements, such as load weight and operational environment. Conducting a thorough comparison of warranties and after-sales services can also safeguard your investment, ensuring reliable support throughout your crane's lifespan.

In addition to performance, safety features should be a significant factor in your selection process. Brands are now prioritizing advanced safety technologies, such as overload protection and emergency stop systems. Always request detailed specifications and user reviews to help gauge the reliability and safety of the equipment you’re interested in.

When considering the investment in overhead bridge cranes, understanding the cost-benefit breakdown is crucial for informed purchasing decisions. These cranes offer significant advantages in industrial settings, including increased efficiency and safety. The initial acquisition cost is often outweighed by the long-term benefits they provide, such as reduced labor costs and minimized risk of workplace injuries. By elevating materials and streamlining workflows, overhead bridge cranes enhance productivity and lower operational downtime.

Moreover, the operational longevity and maintenance aspects play a vital role in the overall cost analysis. A well-maintained overhead bridge crane can last for decades, making it a resilient investment. Additionally, modern cranes come equipped with advanced technology that provides real-time data on performance and maintenance needs, further reducing unexpected repair costs. By evaluating both the upfront investment and the potential for savings over time, buyers can better appreciate the value these cranes bring to their operations, ensuring that funds are allocated effectively towards maximizing productivity and efficiency in their facilities.

Safety is paramount when it comes to operating bridge cranes, and compliance with industry standards is crucial for ensuring a secure work environment. According to the Occupational Safety and Health Administration (OSHA), improper crane operations account for a significant percentage of workplace injuries in construction and manufacturing sectors. Ensuring that your overhead bridge crane meets safety standards like ANSI/ASME B30.2, which addresses the safe use and maintenance of overhead and gantry cranes, is essential for minimizing risks.

When selecting a bridge crane, consider incorporating advanced safety features such as overload protection systems and emergency stop functions. Regular inspections and maintenance, mandated by the National Commission for the Certification of Crane Operators (NCCCO), are also vital for compliance. In fact, a report by the Crane Safety Committee revealed that 45% of crane accidents could have been avoided with more rigorous adherence to safety protocols and training programs.

Tips: Always ensure that your crane operators are certified and have undergone proper training. Implement a routine safety inspection checklist that covers all critical components of the crane. Additionally, stay updated with the latest industry standards and regulations to ensure your operations remain compliant and safe.

Proper maintenance is crucial for enhancing the longevity of overhead bridge cranes.

Regular inspections should be conducted to identify any signs of wear and tear. This includes checking the hoist, trolley, and runway for any issues that could impede performance.

Lubrication of moving parts is essential to reduce friction and prevent premature wear.

Establishing a consistent maintenance schedule can help in spotting potential problems before they escalate into significant failures.

In addition to physical inspections, operators should also prioritize operator training.

Well-trained personnel can better monitor crane performance and recognize any irregularities during operation.

Implementing a daily checklist for operators to follow can ensure that every aspect of the crane is functioning optimally.

Finally, keeping accurate maintenance records enables tracking of service history and facilitates timely interventions, optimizing the crane's performance and extending its operational life.