Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

An Overhead Bridge Crane is a vital piece of equipment in many industries. It helps lift and move heavy loads with ease. This machinery operates on a set of rails fixed to the ceiling, allowing a wide range of movement. Workers can transport materials across large distances without much effort.

Imagine a construction site where large steel beams are lifted high above workers. The Overhead Bridge Crane makes this possible. Its design often includes a hoist and trolley, which facilitate precise load movements. However, relying solely on this crane can introduce risks. Operators need proper training to avoid accidents.

Despite its advantages, not all tasks may suit an Overhead Bridge Crane. Situations arise where the crane's limitations become evident. This may lead to inefficiencies. In some instances, workers might need additional equipment alongside the crane. Recognizing these challenges is key to maximizing productivity and safety in any workspace.

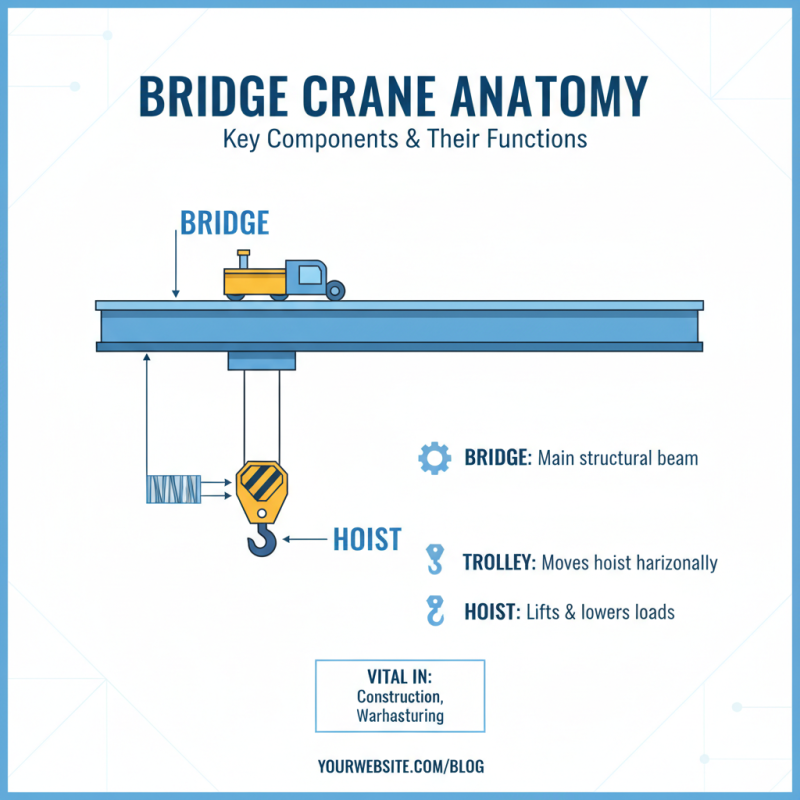

Overhead bridge cranes are essential tools for lifting heavy materials in warehouses and factories. They consist of a bridge that spans a fixed path. The crane moves along this path to transfer loads. Their basic structure typically includes a hoist, trolley, and runway beams. The hoist lifts and lowers objects, while the trolley moves the load horizontally.

Tips: Always check the weight capacity. This ensures safety while using the crane. Regular maintenance is vital to prevent malfunctions.

The design of overhead bridge cranes varies. Some models allow for greater lifting heights, while others focus on compact spaces. Each setup offers unique advantages. However, improper use may lead to accidents or equipment wear. It's crucial to understand the crane’s limitations.

Effective training for operators is a key factor. Knowledge of the equipment ensures safe and efficient operation. Misunderstanding functions can cause serious issues. Regular safety drills can help in keeping skills sharp.

Overhead bridge cranes are vital in various industries, from construction to manufacturing. Understanding their key components helps in effective operation. The main parts include the bridge, hoist, and trolley.

The bridge is the horizontal beam. It spans the workspace, moving along pre-installed rails. This design allows for maximum coverage. The hoist is the lifting mechanism. It holds and raises the load. Typically, hoists can lift thousands of pounds. According to a 2021 report by the American Society of Mechanical Engineers, about 80% of material handling accidents involve improper use of this device.

The trolley runs on the bridge and transports the hoist. Its movement allows for precise load placement. Inspecting these components is crucial. Regular maintenance can prevent costly downtimes. Studies reveal that up to 25% of crane-related incidents stem from component failure. This statistic highlights the importance of diligence. Each part works together to enhance efficiency and safety in operations.

Overhead bridge cranes are essential tools in many industries. They are designed to lift and move heavy loads across large areas. Typically, these cranes consist of a bridge, which spans the width of the work area. The bridge moves along two tracks, allowing precise movement.

The lifting mechanism often involves hoists that use electric motors for power. A recent industry report shows that about 60% of overhead crane accidents result from operator error. This emphasizes the importance of proper training and safety measures.

Operators must be familiar with load limits and operational procedures to mitigate risks.

Moreover, regular maintenance is crucial for ensuring safety and efficiency. Inspections should occur frequently, checking for wear and tear on cables and hoists. The average lifespan of a crane can be around 20 to 30 years, depending on usage and maintenance. Timely servicing can extend this lifespan and improve performance. However, organizations often overlook this, risking costly downtime and accidents.

Overhead bridge cranes are crucial in various industries. They enhance safety while lifting and transporting heavy loads. According to the Material Handling Industry of America, over 90% of manufacturing and warehousing facilities utilize some form of material handling equipment, with bridge cranes playing a significant role.

Industries like construction, steel manufacturing, and shipbuilding heavily depend on these cranes. They efficiently move large components, increasing productivity. A report from the Crane Manufacturers Association of America reveals that the global overhead crane market size is projected to reach $4.35 billion by 2025. This growth reflects the increasing need for advanced material handling solutions.

Despite their advantages, some challenges exist. Maintenance can be demanding. Cranes require regular inspections and repairs, which can disrupt workflows. Additionally, operator training is essential to prevent accidents. The safety of cranes hinges on proper usage and understanding, which not all facilities prioritize. Hence, reflecting on these aspects is vital for ongoing improvement.

Overhead bridge cranes are essential in many industries. They handle heavy loads and improve workflow. Safety is a major aspect when operating these cranes. Operators must be trained properly. They need to understand the crane's features. This ensures safe operation and minimizes risk.

Regular maintenance is crucial for overhead bridge cranes. Inspecting parts like hooks, cables, and brakes is necessary. Operators should watch for wear and tear. Any potential issues need addressing immediately. Neglecting maintenance can lead to accidents. Scheduling routine checks helps maintain safety standards.

Safety protocols should always be followed. Use proper signaling during operation. Clear communication can prevent many accidents. Operators should never rush tasks. A rushed job increases the likelihood of mistakes. Reflecting on safety practices is vital for everyone involved. Taking time to ensure safe operation will pay off in the long run.