Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

Operating an Eot Crane involves significant responsibilities. It is crucial for safety and efficiency. Eot Cranes lift heavy loads, and careful operation is essential. A small mistake can lead to accidents. Understanding its mechanics is not enough. Operators need to stay alert and focused.

Proper training is vital. Many operators overlook this aspect. Without thorough training, errors are more likely to happen. Regular maintenance checks are necessary too. A well-maintained Eot Crane reduces risks. However, some operators forget to inspect their equipment regularly.

Communication on-site matters. Clear signals can prevent accidents. Some may feel confident and skip this step. This can create confusion. Always prioritize safety when operating an Eot Crane. Reflect on past experiences to improve future operations. Each operation provides lessons. Embrace these lessons for safer practices.

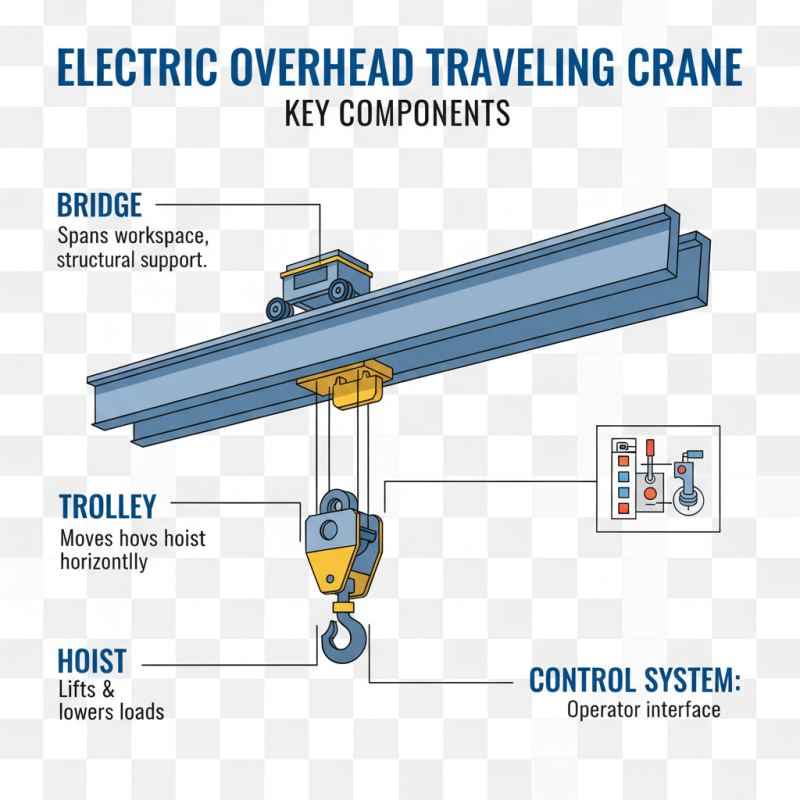

Eot cranes, or electric overhead traveling cranes, are integral in many industrial settings. They consist of several essential components that ensure both safety and efficiency. The main parts include the bridge, trolley, hoist, and control system. Each component plays a critical role in the crane's operation. The bridge spans the length of the workspace, providing the necessary structure for movement.

Understanding how each part interacts is crucial. The trolley, for example, moves side to side along the bridge. It's connected to the hoist, which lifts and lowers the load. Operators must familiarize themselves with the control system. Operators should take their time to learn the controls fully. Many overlook this step, leading to potential errors during operation.

Regular maintenance of these components is vital. Neglecting it can result in serious accidents. Identifying wear and tear can prevent equipment failure. Training programs should emphasize this aspect. Operators sometimes skip these checks, assuming everything is fine. However, it can cost them dearly in the end.

Operating an EOT crane requires strict adherence to safety protocols and regulations. Operators must wear personal protective equipment, including hard hats and safety shoes. Before starting, check the equipment for any defects. A visual inspection can reveal issues like frayed cables or loose bolts. These small checks make a significant difference.

Training is vital for all crane operators. Each team member should understand the signals used during operation. Miscommunication can lead to accidents. Regular drills can enhance familiarity with safety procedures. Communication should also involve ground personnel. They must remain alert and aware of their surroundings.

Staying updated on local regulations is crucial. Each region may have different requirements regarding crane operation. Operators should regularly review any changes. Sharing knowledge within the team can create a safer working environment. Even with proper training, complacency can lead to mistakes. Reflecting on past incidents can uncover areas for improvement. Identify opportunities for better safety practices and ensure ongoing education in crane operation.

When operating an EOT crane, conducting pre-operational checks is vital. These checks help prevent accidents and ensure efficient operation. According to industry reports, nearly 30% of crane accidents stem from inadequate inspections. Therefore, it’s crucial to start every day with a thorough inspection list.

Tip: Always check for visible wear on cables and chains. Look for any signs of corrosion or fraying. Damage can lead to catastrophic failures. Inspect brakes, controls, and lights too. A crucial part of the check is the load limit. Know your crane's capacity. Operating beyond its limit can cause tipping incidents.

Reviewing operational records is essential. Past performance can highlight recurring issues. It's important to address these problems proactively. Training for operators should include feedback mechanisms. This helps to refine the operational process.

Tip: Establish a checklist that operators can follow. Simple checklists can reduce oversight. They should cover all components that require inspection. Regular maintenance should also be scheduled. Ignoring these simple tasks can lead to dangerous situations. The right preparation is key to safe and effective EOT crane operation.

Proper operating techniques are crucial for the safe use of an EOT crane. Start by understanding the crane's control panels and their functions. A clear grasp of these elements helps in reducing errors. Familiarize yourself with load capacities and limitations. Knowing how much weight you can safely lift prevents accidents.

Load handling is an art. Always inspect the load before lifting. Check for stability and balance. Use appropriate rigging techniques to secure the load. Avoid sudden maneuvers; they can cause the load to swing unexpectedly. This can lead to dangerous situations.

Communication is key among operators and ground personnel. Use clear signals and maintain eye contact. Miscommunication can result in costly mistakes. However, sometimes signals can be overlooked or misunderstood. Frequent training and drills on communication can help eliminate these errors. Reflecting on past experiences can lead to improvements in safety practices. Every lifting operation offers a chance to learn and enhance skills.

| Dimension | Details |

|---|---|

| Operator Training | All operators must complete a certified crane operation training program. |

| Inspection Frequency | Daily pre-operation inspections and monthly comprehensive inspections. |

| Load Limit | Never exceed the rated load capacity specified by the manufacturer. |

| Signal Protocol | Use standardized hand signals or radio communication for effective load handling. |

| Area Awareness | Maintain a clear work area and ensure no personnel are in the swing radius of the crane. |

| Weather Conditions | Do not operate the crane in adverse weather conditions such as high winds or rain. |

| Emergency Procedures | Establish and rehearse emergency shut-down procedures for quick response. |

| Maintenance Schedule | Regular maintenance checks should be conducted in accordance with the manufacturer's recommendations. |

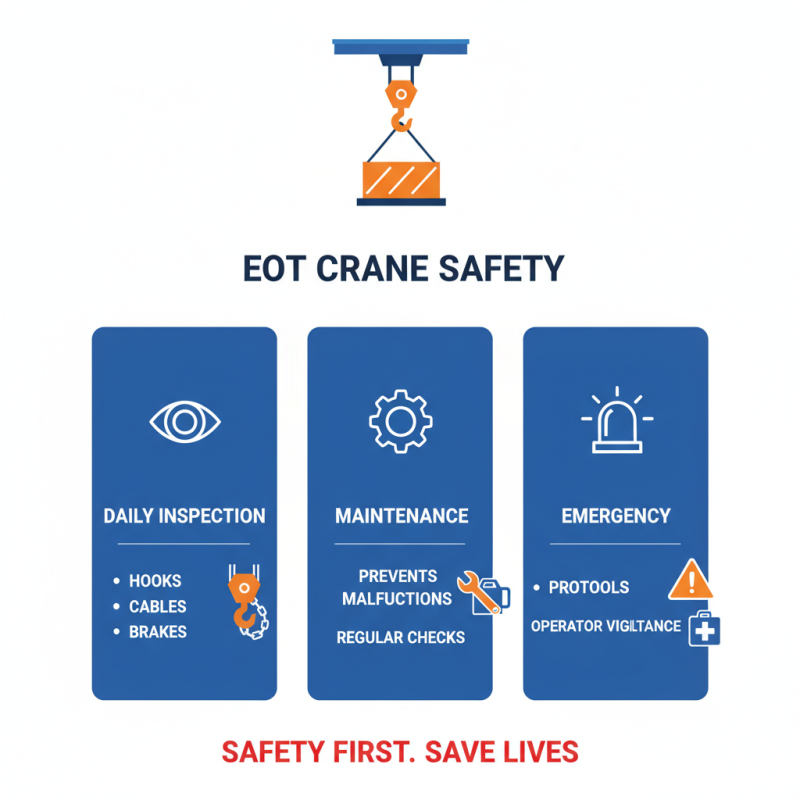

Operating an EOT crane requires strict adherence to safety protocols and effective emergency procedures. Regular maintenance practices play a vital role in ensuring that cranes function properly. Inspecting hooks, cables, and brakes should occur daily. Any signs of wear can lead to accidents. Operators must be vigilant. A simple inspection can prevent a mishap that could endanger lives.

In emergencies, having a clear action plan is essential. Operators should know how to shut down the crane quickly. Training on emergency procedures should be frequent and thorough. Role-playing scenarios can help identify gaps in knowledge. Everyone must practice these drills. The importance of clear communication cannot be overstated. A cramped workspace can lead to confusion. Clarity in command can save time and lives.

Maintenance practices shouldn't be an afterthought. Schedule regular check-ups to detect issues early. Keeping a log of maintenance helps track performance over time. Documented procedures can remind operators about their roles too. Reassessing procedures often will improve efficiency. Reflecting on past experiences can lead to better practices in the future. Recognizing the potential for human error can guide necessary changes. Safety is an ongoing process, not a one-time effort.