Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

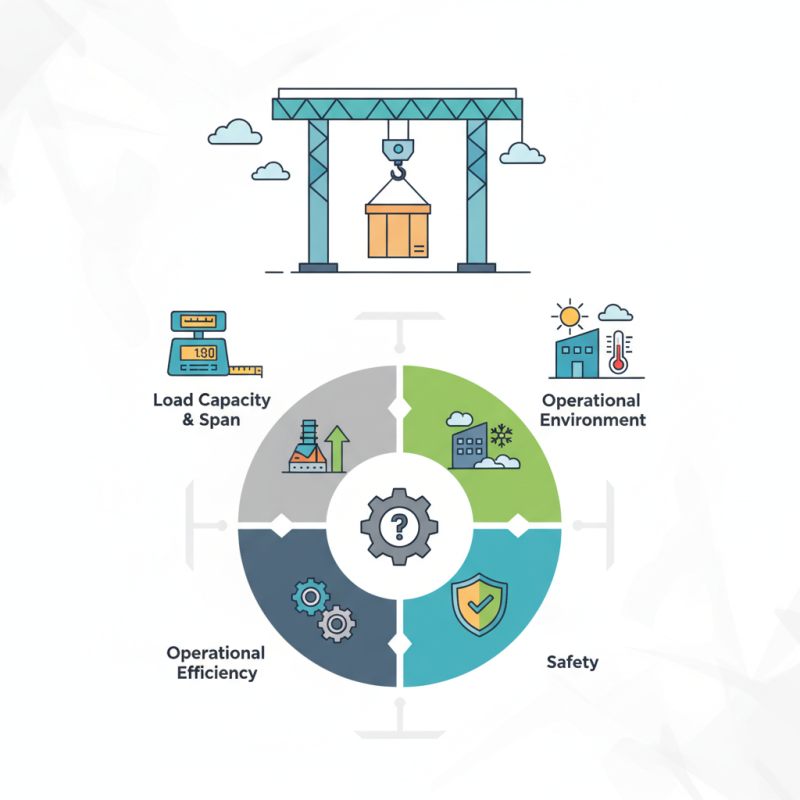

Choosing the right overhead crane is crucial for operational efficiency. According to industry expert John Smith, "Selecting the correct overhead crane can enhance productivity and ensure safety." The right crane meets specific needs. Various factors influence this decision.

Consider your load capacity and span requirements. Different overhead cranes are designed for different tasks. A mismatch can lead to safety risks or inefficiency. Often, companies overlook these details, leading to costly mistakes.

Another aspect is the environment in which the crane will operate. Indoor use, outdoor exposure, and temperature variations all matter. Ignoring these factors can compromise the crane's performance. Carefully assessing your needs will prevent regrets later. Ensuring you make an informed choice is essential.

Overhead cranes are essential in various industries. They help lift and move heavy loads efficiently. Understanding their key components is vital when selecting one for your needs. Cranes typically consist of a hoist, bridge, and trolley system. These elements work together to create a seamless operation. A report by the Crane Market Report indicates that the global overhead crane market is projected to reach $4.6 billion by 2024, highlighting its significance.

When choosing an overhead crane, consider the lifting capacity and span. An average overhead crane can lift between 1 to 100 tons. However, severity plays a role in efficiency and safety. Choosing the wrong capacity can lead to operational risks. Improper weight distribution may cause accidents. Many facilities face challenges due to insufficient training or understanding of load limits.

Work environment matters as well. Overhead cranes may not function well in extreme conditions such as high-temperature areas. According to industry surveys, about 25% of crane failures are due to environmental factors. Regular inspections are necessary to ensure longevity and safety. The balance between cost and quality cannot be overlooked. A cheaper option may save money but could lead to future costs in repairs or accidents.

| Feature | Description | Considerations |

|---|---|---|

| Load Capacity | Maximum weight the crane can lift. | Ensure it exceeds your heaviest load. |

| Span Length | Distance between the supports of the crane. | Measure your workspace to select appropriate span. |

| Height of Lift | Maximum vertical distance the crane can lift loads. | Consider the height of your workspace and equipment. |

| Power Source | Energy source for the crane, e.g., electric, manual. | Choose based on availability and efficiency. |

| Control System | Type of operation, such as remote or wired controls. | Consider ease of use and safety features. |

| Environment | Operating conditions, such as indoor or outdoor use. | Select a crane built for specific environmental challenges. |

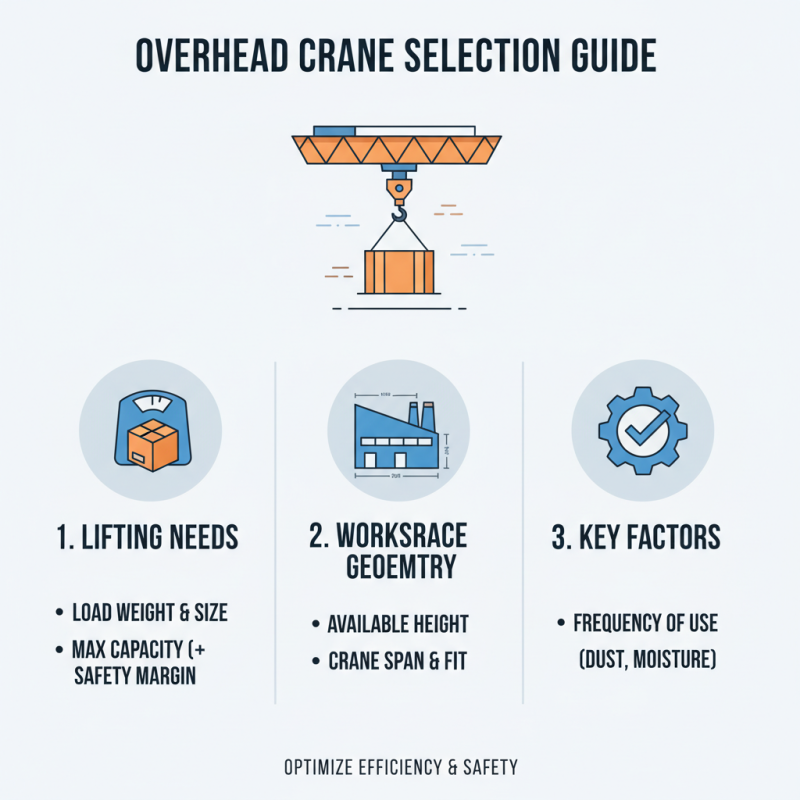

Choosing the right overhead crane depends largely on understanding your specific lifting needs. Assessing the weight and dimensions of the loads you frequently handle is essential. Consider the maximum weight capacity of the crane. It should exceed your heaviest load to avoid any strain. Also, look at the geometry of your workspace. Is there enough height? Will the crane fit? These factors influence your decision significantly.

**Tips:** Evaluate your current and anticipated future loads. This helps in selecting a crane that not only meets your current need but also future challenges. Sometimes, businesses underestimate their lifting capacities.

Additionally, think about the environment where the crane will operate. Indoor versus outdoor usage can dictate the type of crane you need. Equipment used in harsh conditions should be durable. Pay attention to potential obstacles in your workspace. These can limit movement or pose risks during operations.

**Tips:** Analyze your workflow. A crane that complicates daily tasks may not be the best fit. Errors in space assessment can lead to costly adjustments later. Consider what suits your operational flow best.

Choosing the right overhead crane requires understanding various types and their specific applications. For example, bridge cranes are ideal for moving heavy loads across long distances. They are common in manufacturing and warehouse settings. According to industry reports, about 60% of factories utilize bridge cranes due to their efficiency and reliability in heavy lifting tasks.

Gantry cranes offer flexibility for outdoor applications. They can be adjusted to fit various workspace dimensions. In construction sites, gantry cranes are favored for their mobility and versatility. However, their initial investment can be higher than other options. Organizations must evaluate budget constraints when selecting a crane type.

**Tip:** Always analyze the load capacity before making a decision. Overloading can lead to accidents.

Choosing the wrong crane can create challenges. For instance, a lightweight crane may struggle with heavy materials, leading to operational delays. Regular assessments of crane performance and suitability to tasks are essential. Inadequate machinery can hinder productivity and safety.

**Tip:** Conducting a site survey can reveal the best crane fit for your environment.

Choosing the right overhead crane requires careful assessment of space constraints and environmental factors.

First, consider the available space. Narrow aisles or low ceilings may limit crane size and movement.

A report by the Crane Manufacturers Association of America noted that 70% of crane-related issues stem from improper sizing for designated spaces.

Evaluating your layout can prevent costly downtime and inefficiencies.

Next, environmental conditions play a crucial role.

Factors such as temperature extremes, humidity, and dust levels can impact crane performance.

Cranes need to withstand specific environments, and neglecting this can lead to frequent failures.

Studies indicate that over 30% of cranes operating in harsh conditions suffer from maintenance issues.

Reviewing these conditions ensures long-term reliability.

Don’t overlook safety features. Cranes operating in confined spaces often require additional safety measures.

Injuries can arise from limited visibility or unexpected obstacles.

Incorporating advanced sensors and cameras may improve operational safety.

Remember, these adjustments might seem costly upfront, but they provide return on investment through reduced accidents and maintenance needs.

When selecting an overhead crane, consider its features carefully. The lifting capacity is crucial. It should match or exceed the weight of the loads you intend to move. For example, if you're regularly lifting bulky materials, choose a crane that can handle more than you expect. Safety features also matter. Anti-collision systems and emergency stops can prevent accidents.

Next, think about the crane's design. Is it the right height and span for your workspace? Ensure it fits comfortably in your operational area. Adjustable speeds can enhance control during lifts. Flexibility in operation is vital; a crane that can adapt is always a plus.

Don’t overlook maintenance requirements. Some cranes need more upkeep than others. If maintenance is challenging, it could impact your workflow. Reflect on these elements. Choosing the right specifications needs careful consideration. A wrong choice can lead to frustration and extra costs. It's important to balance features with your operational needs.

This chart represents the key specifications that should be considered when choosing an overhead crane. Load capacity, span, height, speed, and control type are essential features that impact the crane's performance and suitability for specific tasks.