Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

Choosing the right Over Head Bridge Crane is crucial for optimizing operational efficiency and ensuring safety in various industrial applications. With a wide range of options available, it can be daunting for businesses to identify the most suitable crane that meets their specific needs. Factors such as load capacity, span, height of lift, and the environment in which the crane will operate play significant roles in this decision-making process.

In this guide, we will explore the essential considerations that should be taken into account when selecting an Over Head Bridge Crane. Understanding the unique requirements of your facility and the materials you handle will enable you to make informed choices that enhance productivity while minimizing costs. From understanding the mechanical configurations to evaluating the necessary safety features, this overview aims to provide clarity in a complex selection process, empowering you to choose a crane that perfectly aligns with your operational demands.

Overhead bridge cranes are essential tools in various industrial applications, from manufacturing to shipping. Understanding their basics is crucial for making informed decisions about which crane best suits your operational needs. These cranes consist of a horizontal beam supported by end trucks that travel along elevated tracks. They are designed to lift and move heavy loads efficiently, typically in environments where floor space is limited. Their versatility makes them suitable for tasks such as material handling, assembly processes, and warehousing.

When choosing an overhead bridge crane, consider the maximum load capacity you require. Understanding the weight of the loads you will lift ensures you select a crane that can handle your specific needs without risking safety. Additionally, evaluate the span of the crane and the height of your facility to ensure compatibility with your workspace.

Tips: Assess the environment where the crane will be used. Factors such as temperature, humidity, and the presence of dust can influence the type of crane needed. Furthermore, consider the operational frequency; if your operations are continuous, investing in a more robust design may be beneficial. Regular training for operators is also crucial to maximize safety and efficiency when working with overhead bridge cranes.

| Crane Type | Load Capacity | Span Length | Lift Height | Use Case |

|---|---|---|---|---|

| Single Girder | 1-10 Tons | 10-20 ft | 10-15 ft | Light to Medium Duty |

| Double Girder | 5-50 Tons | 20-60 ft | 15-30 ft | Heavy Duty Applications |

| Jib Crane | 0.5-5 Tons | 8-20 ft | 5-10 ft | Workshops and Assembly Lines |

| Portal Crane | 10-80 Tons | 30-100 ft | 20-40 ft | Outdoor Construction Sites |

When selecting an overhead bridge crane, several key factors must be taken into account to ensure optimal performance for your specific needs. One of the primary considerations is the load capacity. According to a recent industry report from the American Crane and Hoist Manufacturers Association, the demand for cranes with load capacities ranging from 1 to 20 tons has increased by over 30% in the last five years. Understanding the weight of the materials you'll be handling is crucial to selecting a crane that can safely and efficiently manage those loads.

Another essential factor to consider is the span of the crane. The span is the distance between the runway beams and affects both lifting capability and space utilization. A study by the National Productivity Council indicates that optimizing crane span can enhance lifting efficiency by up to 25%. With this in mind, it is important to assess the layout of your facility and any obstacles that may require a specific crane design, such as lower headroom or restricted space. Additionally, using cranes with adjustable spans can provide greater flexibility for future expansions or changes in operations.

When selecting an overhead bridge crane, understanding the various types and their specific applications is crucial for optimizing efficiency and safety in your operations.

The two primary categories of overhead bridge cranes are single girder and double girder cranes.

Single girder cranes are ideal for lighter loads, typically ranging from 1 to 10 tons, and are commonly used in smaller facilities with limited space.

Their design allows for easier installation and maintenance, making them a cost-effective choice for tasks such as light manufacturing and assembly work.

On the other hand, double girder cranes are better suited for heavy-duty applications, capable of handling loads exceeding 10 tons.

Their robust design offers greater stability and lifting height, making them an excellent option for large warehouses, shipping yards, or factories with significant operational demands.

In addition to these main types, there are specialized cranes like those equipped with hoists designed for particular tasks, such as magnetic or grab cranes, that can increase efficiency when handling specific materials.

Each crane type offers unique advantages, and understanding their functionalities can help you choose the right equipment for your specific needs.

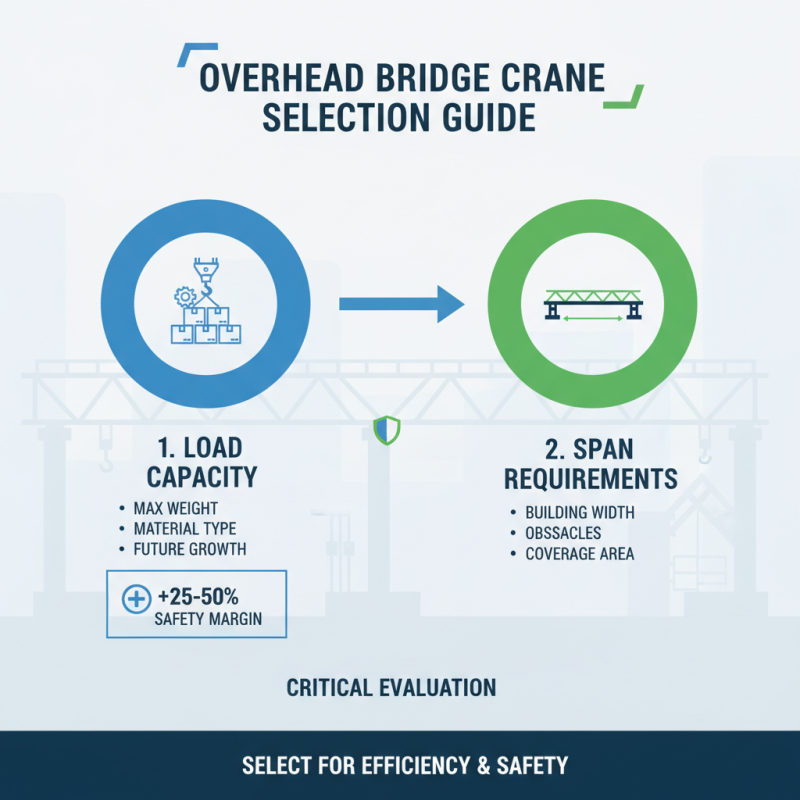

When selecting the right overhead bridge crane for your needs, evaluating the load capacity and span requirements is critical. The load capacity is determined by the weight of the materials you will be handling. It is essential to consider not just the maximum weight but also the types of loads that may change over time. Incorporating a safety margin is recommended, typically adding an extra 25% to 50% to your estimated load capacity to account for unexpected circumstances.

The span of the crane is equally important, as it dictates the distance the crane can cover. Measure the width of your workspace and ensure the crane can reach all areas where materials will be moved. If your operations require longer spans, you may need to invest in a specialized crane that can handle these demands without compromising safety and efficiency.

**Tips:**

1. Always consult with a structural engineer to assess your facility’s capability to support the crane and its load.

2. Review the crane’s specifications in relation to your specific operation to ensure it meets your production needs without excessive downtime.

When selecting the appropriate overhead bridge crane, it is essential to prioritize maintenance and safety considerations to ensure optimal performance and longevity. According to the National Safety Council, approximately 4,800 injuries occur annually in the United States due to crane-related incidents. This statistic underscores the importance of regular maintenance, which can significantly reduce the risk of accidents and enhance operational efficiency. Regular inspections, including checking for wear and tear on hoists, hooks, and rails, can help identify potential issues before they escalate into serious problems.

In addition to maintenance, safety protocols must be a priority for operators and employees. The American Society of Mechanical Engineers (ASME) recommends adhering to guidelines such as training operators thoroughly, implementing proper signaling, and performing regular safety audits. Utilizing features like limit switches and emergency stop buttons can further enhance safety. Furthermore, a report from the Occupational Safety and Health Administration (OSHA) highlights that proper load management and understanding the crane's specifications are crucial to prevent tipping and other hazardous situations. Adopting a culture of safety through continuous education and adherence to recommended practices is vital to maximizing both the safety and efficiency of overhead bridge cranes in any operational setting.