Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In the world of material handling, choosing the right Gantry Crane is crucial. "Selecting the proper crane can make or break your project," says John Smith, an expert in the Gantry Crane industry. His insights highlight how essential it is to match the crane's specifications with your project's demands.

Gantry Cranes are versatile machines designed for different applications. Their design varies depending on the weight capacity, height, and mobility needed. A project requiring frequent load movement may benefit from a mobile Gantry Crane. Conversely, if stability is key, a stationary model might be a better choice.

Understanding the nuances of Gantry Cranes is vital, yet many overlook this crucial step. Often, users rush into buying decisions, leading to potential operational setbacks. Consider your specific needs carefully to avoid regrets later. A well-informed choice can enhance productivity and safety on the job site.

Gantry cranes are essential for various lifting tasks. Understanding their basics helps in making informed decisions for projects. These cranes consist of two vertical legs and a horizontal beam. They can be stationary or movable, depending on the needs of your project. Their ability to span large areas makes them ideal for warehouses and construction sites.

Think about the weight capacity you require. Some projects may demand a crane that can lift several tons. Taking accurate measurements of your workspace is crucial. If the crane is too large, it won't fit; if too small, it won't perform. Material choice also matters. Steel is durable but heavy. Aluminum is lighter but may not be suitable for heavy loads.

Consider the terrain as well. A flat surface is optimal for stability. On uneven ground, the crane may struggle. Be prepared for adjustments. Safety features should never be overlooked. Evaluate if additional supports or alarms are necessary. Reflect on these elements to ensure your chosen gantry crane meets all your project demands.

When selecting a gantry crane, understanding load requirements is crucial. Start by assessing the maximum weight you need to lift. According to industry reports, more than 30% of projects fail due to underestimating load capacity. Knowing the precise weight ensures you choose a crane that meets your expectations.

Consider the dimensions of your loads as well. Height and width play a significant role in crane selection. Cranes can be highly specialized. Some might support large, bulky items while others are built for more compact loads. In 2022, a survey revealed that about 25% of users experienced issues due to improper load sizing. This miscalculation often leads to workplace inefficiencies.

Take into account the lifting height and radius as well. This enhances crane effectiveness. The required lifting height varies by project. For example, construction sites often need cranes that can reach 20 feet or more. Also, a crane with a wider radius can handle a larger workspace. It’s essential to reflect on these requirements to avoid costly mistakes later. Identifying specifications before making a decision helps optimize your operation.

When evaluating different types of gantry cranes, consider their design and function. There are various styles available, such as full gantry, semi-gantry, and portable cranes. Each type serves unique purposes. For instance, full gantry cranes are ideal for heavy lifting in large areas. They offer excellent stability and lifting capacity.

Portable gantry cranes are more versatile. They can be easily moved and set up in different locations. However, they usually have lower weight capacities. Each type has its advantages and limitations. Sometimes, it feels challenging to choose the right one.

Make sure to assess your specific needs. Think about the weight and size of the loads. Evaluate the space where the crane will operate. Also, consider safety features. Not all models perform equally well in various environments. A wrong choice can lead to inefficiencies or potential safety hazards. Always reflect on your requirements carefully before making a decision.

When selecting a gantry crane, understanding environmental and space constraints is crucial. The area where you intend to install the crane plays a key role in deciding its specifications. According to a 2022 industry report, 40% of construction projects face delays due to inadequate space planning. It’s essential to measure the site accurately and account for obstacles like buildings or power lines. A compact design may be necessary if room is limited.

Additionally, consider the local environment. Factors such as wind speed and temperature can affect crane performance. A study noted that cranes in areas with high winds require more robust designs. In regions prone to extreme weather, selecting materials that withstand harsh conditions becomes vital. Ensure compliance with local regulations, as they often dictate design and safety standards, affecting your overall project timeline and budget.

Ultimately, many overlook these critical aspects, leading to costly modifications later. Poor installation planning can lead to accidents. Take time to analyze site conditions and environmental factors. This approach will save money and create a safer work environment.

| Criteria | Details |

|---|---|

| Load Capacity | Determine the maximum weight you need to lift, usually ranging from 500 lbs to 10 tons. |

| Span Length | Consider the width of the area where the crane will operate, typically between 10 to 40 feet. |

| Height Requirements | Ensure enough vertical space for operation; standard heights range from 10 to 20 feet. |

| Power Supply | Identify if the crane needs electric, diesel, or manual operation based on site requirements. |

| Environmental Conditions | Evaluate outdoor vs indoor use, temperature extremes, and presence of corrosive materials. |

| Mobility | Decide if a fixed or mobile gantry crane is more suitable for your project. |

| Budget Constraints | Define the budget for your project, which can affect the type and features of the crane. |

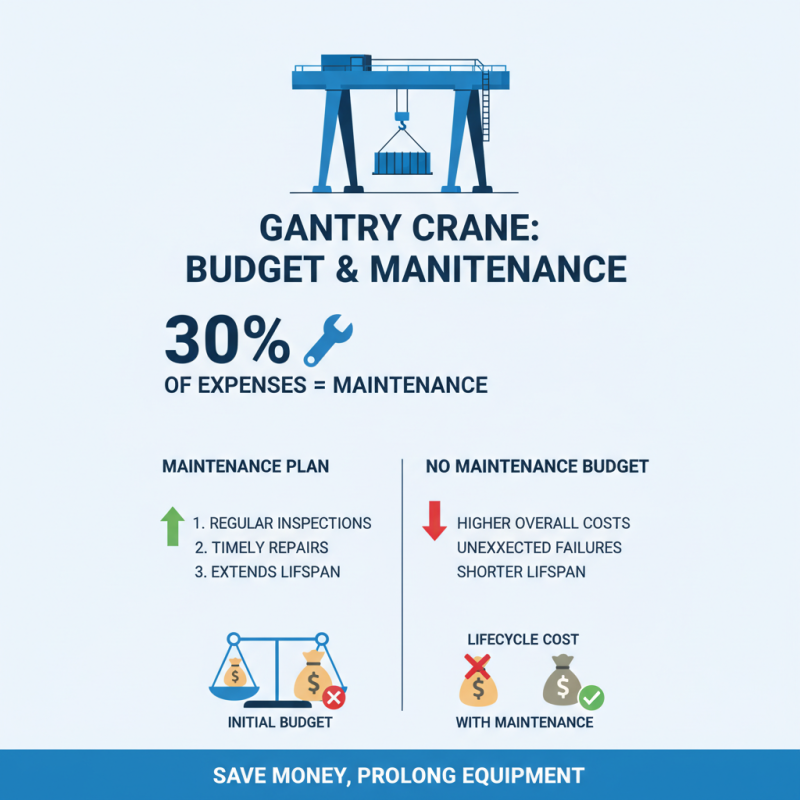

When choosing a gantry crane, budget and maintenance are crucial considerations. Industries report that nearly 30% of expenses stem from equipment maintenance. A solid maintenance plan can extend a crane's lifespan significantly. Regular inspections and timely repairs can mitigate unexpected costs. Failing to budget for maintenance often leads to higher overall expenses.

Another factor is the initial cost of the crane. Depending on its size and capabilities, the price can vary significantly. For example, smaller cranes may start at around $5,000, whereas larger models can exceed $100,000. Many companies underestimate the long-term investment involved. A lower purchase price might lead to higher maintenance costs in the future. The ideal crane should balance these two aspects effectively.

It's essential to consider spare parts availability and service support. A lack of accessible parts can lead to prolonged downtime. The industry average states that cranes require maintenance every 1,000 operating hours. This translates to frequent checks and possible downtime. Companies must plan for these factors to avoid operational disruptions. Engaging with professionals can help identify the right balance for your needs.