Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

Choosing the right Over Head Cranes for your business is crucial. Industry expert John Smith states, “The right crane can make or break your operational efficiency.” His insight emphasizes the importance of making an informed decision.

Over Head Cranes come in various types and sizes. Each option serves specific needs. It's vital to assess your operational requirements. Will you lift heavy loads frequently? Understanding the weight capacity is essential. Additionally, consider the space available for installation. Cranes may require significant vertical and horizontal clearance.

In the complex world of industrial lifting, choices can overwhelm. Many businesses struggle to find the perfect fit. Factors like frequency, weight, and space often lead to confusion. End up buying a crane that doesn’t meet needs? Reflection on these aspects is key. Making a hasty decision could cost both time and money. Take the time to evaluate before making a commitment.

When selecting an overhead crane, understanding the types available is crucial. There are several types on the market. For instance, bridge cranes are common in large warehouses. They run on tracks fixed to the ceiling. This design allows for considerable lifting capacity, ideal for heavy loads.

Another option is the jib crane. These models have a rotating arm. They are great for small areas and can lift materials with precision. However, they may not handle very heavy weights well. Then, there are gantry cranes, which can be movable. They are versatile and can adapt to different spaces. Their flexibility is appealing, but the setup can be complex and requires enough space.

Each type comes with strengths and weaknesses. Bridge cranes offer heavy lifting but may not fit all buildings. Jib cranes are easier to operate, yet limited in weight capacity. Gantry cranes offer flexibility, but cost may be a concern. Careful consideration of your needs is essential when making a choice. Avoiding a rushed decision can save time and money later.

When selecting overhead cranes, it’s crucial to assess your business's specific lifting needs. Different industries have varying requirements. For instance, the construction sector often demands cranes that can handle heavy loads with precision. According to a recent industry report, nearly 70% of businesses prefer cranes with a lifting capacity of 10 tons or more for large-scale projects.

Consider the materials you handle. If your business involves delicate materials, a smoother, more controlled lifting mechanism is essential. Some reports indicate that 45% of workplace accidents arise from improper lifting equipment. This highlights the need for careful consideration in your choice. Additionally, think about the space where the crane will operate. Low ceilings may limit your options. Don't overlook maintenance needs. Regular checks are vital to avoid accidents and extend equipment life.

It can be tempting to go for the most robust option available. However, matching a crane's capabilities to your actual needs often leads to better efficiency. Choosing a crane that’s too powerful may result in unnecessary costs and complexities. Also, consider the training required for your team. More complex cranes need more skilled operators. Understanding your specific needs will ultimately guide you to an appropriate crane selection that balances safety and functionality.

Evaluating load capacity is crucial when selecting overhead cranes. A crane's load capacity determines the maximum weight it can safely lift. Most industrial cranes range from 1 ton to 50 tons. However, larger models can lift up to 100 tons or more. Selecting the right capacity is vital for safety and efficient operations. Underutilizing a crane wastes resources. Overloading can lead to accidents and mechanical failures, resulting in injuries or financial loss.

Safety features in overhead cranes are equally important. A recent industry report noted that 23% of workplace accidents involve lifting operations. Thus, investing in cranes with safety systems is smart. Look for features like redundant braking systems, limit switches, and overload alarms. A study indicated that cranes equipped with these safety features experience 50% fewer incidents. Regular inspections and maintenance are also critical. Ignoring these aspects leads to performance risks and could invalidate warranties.

In the end, choosing the right overhead crane involves more than just load capacity or safety features. Business owners must also evaluate operational needs and space constraints. The perfect crane for one operation might fall short in another. Always consider the specific application. Balancing these factors can be challenging but necessary for successful operations.

When selecting the right overhead cranes, space constraints play a crucial role. Measure your workspace carefully. Consider the ceiling height and the available floor area. A crane that is too large may restrict movement. Also, a low ceiling can limit your options. Evaluate the type of materials you will lift. Heavier items often require different designs.

Installation requirements are just as essential. Ensure you have the right infrastructure for support. The floor should be level and strong enough to handle the load. If installation involves extensive modifications, it may increase costs. Think about the type of energy supply needed for operation. Can your facility accommodate it?

Sometimes, decision-making involves trade-offs. You may want a more powerful crane, but space is limited. Future growth of your business can also be a factor. Balancing immediate needs with long-term goals is challenging. Reflect on how often you might need to relocate equipment in the future. If flexibility is essential, consider adjustable options.

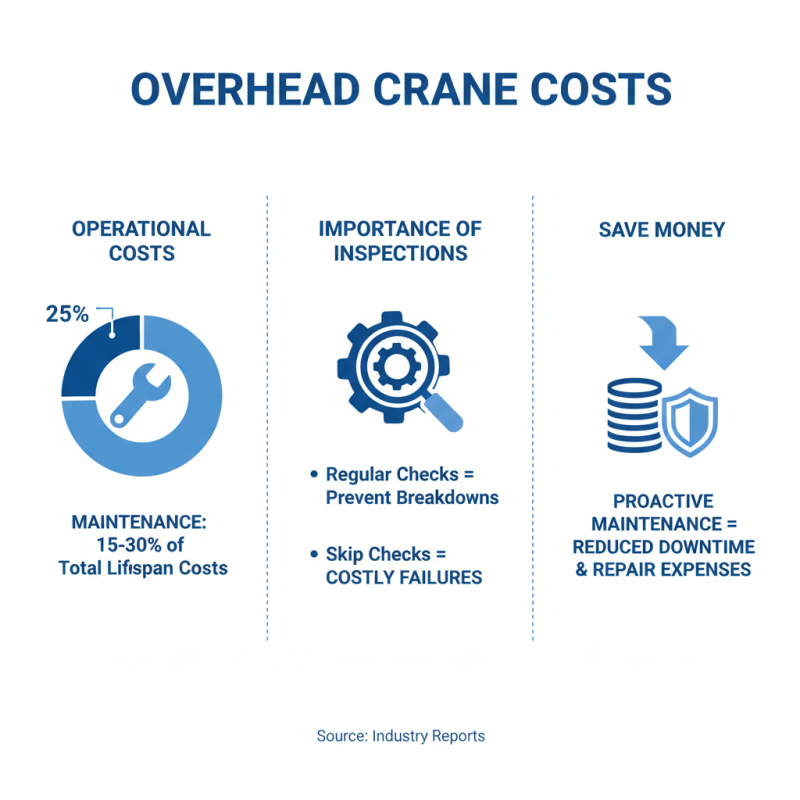

When considering overhead cranes, it's essential to analyze maintenance and operational costs. According to industry reports, maintenance can account for 15-30% of total operational costs over the crane's lifespan. Regular inspections are crucial. Skipping them can lead to costly breakdowns.

Operational costs are also influenced by energy consumption. A poorly selected crane could consume up to 40% more energy than needed. This inefficiency translates to higher monthly bills and a larger carbon footprint. For instance, using electric cranes versus hydraulic can save significant energy costs.

Additionally, training workers on proper crane operation is often overlooked. Investing in training can reduce accidents and subsequent repair costs. Without proper knowledge, misuse can lead to equipment failure. Companies might find themselves facing unexpected expenses due to lapses in training and maintenance.