Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

When it comes to optimizing your facility's material handling capabilities, selecting the right Over Head Bridge Crane is crucial. Industry expert John Smith, a seasoned engineer with over 20 years of experience in crane design and implementation, emphasizes the importance of understanding your specific needs by stating, "The right Over Head Bridge Crane can not only improve safety but also enhance productivity and efficiency in your operations."

Choosing the right crane involves several considerations, including load capacity, span, and the operational environment. Proper evaluation of these factors will enable you to make an informed decision that aligns with your facility's unique requirements. Furthermore, consulting with experts in the field can provide invaluable insights, ensuring that you select a crane that maximizes performance while minimizing operational risks.

As you navigate the selection process, remember that investing time in understanding the various options available can lead to significant long-term benefits. By taking the necessary steps to choose the appropriate Over Head Bridge Crane, you set the stage for a safer and more efficient working environment.

When selecting the right overhead bridge crane for your facility, understanding your load handling requirements is critical. According to a report by the Occupational Safety and Health Administration (OSHA), improper load handling can lead to serious accidents and injuries, emphasizing the necessity of precise calculations concerning the weights and dimensions of the loads your facility will manage. Facilities should begin by conducting a thorough analysis of their material inventory, considering both the maximum weight and the type of materials to be moved. For instance, a study published by industry experts indicates that facilities handling heavy and bulky items may require cranes with higher tonnage ratings and specialized features such as spreader beams or lifting magnets.

In addition to load weight, it’s equally essential to assess the frequency and duration of use. The Crane Manufacturers Association of America (CMAA) categorizes cranes into different classes based on their operational environment and usage patterns. Facilities dealing with continuous operations might need cranes that can withstand heavy usage, while those with sporadic lifting requirements may opt for lighter-duty models. Understanding these dynamics will help businesses make informed decisions about the crane’s capacity, ensuring both efficiency and safety in their operations. With proper evaluation of load handling needs, facilities can effectively align their crane specifications with operational demands.

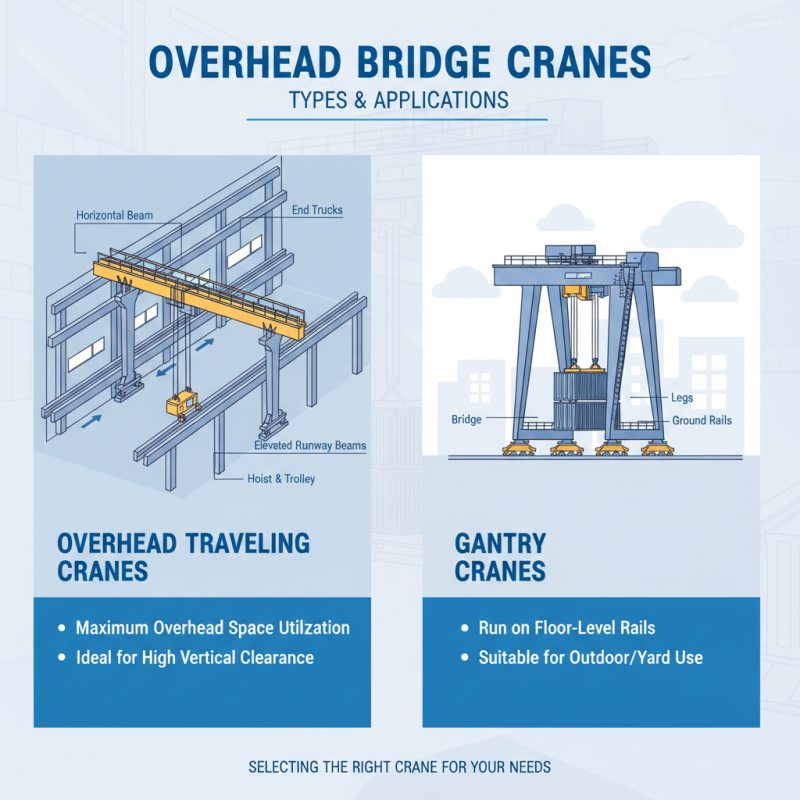

When selecting an overhead bridge crane for your facility, it is essential to understand the different types available, as each design caters to specific operational needs. The two primary types of overhead bridge cranes are overhead traveling cranes and gantry cranes. Overhead traveling cranes typically consist of a horizontal beam supported by two end trucks that move along elevated runway beams, providing maximum utilization of overhead space. They are ideal for applications requiring substantial vertical height and can be customized with various hoist options for heavy lifting.

On the other hand, gantry cranes are designed to operate at ground level and are supported by legs that straddle the work area. This type is more versatile for outdoor usage or in facilities where the installation of overhead runways is impractical. Gantry cranes are often portable, making them suitable for project-based tasks, while their adjustable height offers flexibility for diverse lifting applications. Understanding these fundamental differences enables facility managers to choose a crane type that not only aligns with their spatial constraints but also meets their operational demands effectively.

When selecting an overhead bridge crane, one of the first steps is to evaluate your facility's available space and environmental conditions. According to a report by the Crane Manufacturers Association of America (CMAA), 60% of overhead crane systems are improperly configured due to insufficient consideration of site constraints. This can lead to underutilization of space and, ultimately, operational inefficiencies. To maximize productivity, it is essential to analyze factors such as ceiling height, floor space, and load capacity requirements, ensuring that the crane can operate effectively within its designated area.

Environmental factors also play a critical role in the decision-making process. The Occupational Safety and Health Administration (OSHA) identifies specific conditions, such as high temperatures, moisture levels, and the presence of dust or corrosive elements, which may necessitate specialized crane designs. For instance, facilities subject to extreme temperatures might require cranes made from materials that can withstand these conditions without compromising operational integrity. Research from the American Society of Mechanical Engineers (ASME) indicates that 35% of crane failures can be traced back to inadequately addressing environmental stresses. Thus, it is imperative to conduct a thorough evaluation of your facility's environmental challenges to select an overhead bridge crane that ensures both safety and efficiency.

| Crane Type | Load Capacity (tons) | Span (ft) | Lift Height (ft) | Power Source | Environment |

|---|---|---|---|---|---|

| Single Girder Crane | 5 | 20 | 10 | Electric | Indoor |

| Double Girder Crane | 10 | 30 | 15 | Electric | Indoor/Outdoor |

| Jib Crane | 2 | 10 | 8 | Manual | Indoor |

| gantry Crane | 8 | 25 | 12 | Electric | Outdoor |

When selecting an overhead bridge crane for your facility, safety standards and compliance regulations must be at the forefront of your decision-making process. According to the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), cranes are one of the most regulated pieces of equipment in industrial settings. Compliance with these standards ensures not only the safety of employees but also protects the integrity of operations. In fact, OSHA reports indicate that proper adherence to crane safety protocols can reduce accidents and injuries by up to 70%.

In addition to general compliance, facilities should conduct a thorough risk assessment to identify specific safety needs associated with their operations. This includes evaluating load capacities, environmental conditions, and workspace constraints. The Crane Manufacturers Association of America (CMAA) provides comprehensive guidelines that further assist in establishing safety compliance tailored to the unique demands of different work environments. By integrating these safety standards into the crane selection process, decision-makers can not only ensure a safer workplace but also improve operational efficiency, thereby leading to overall better productivity.

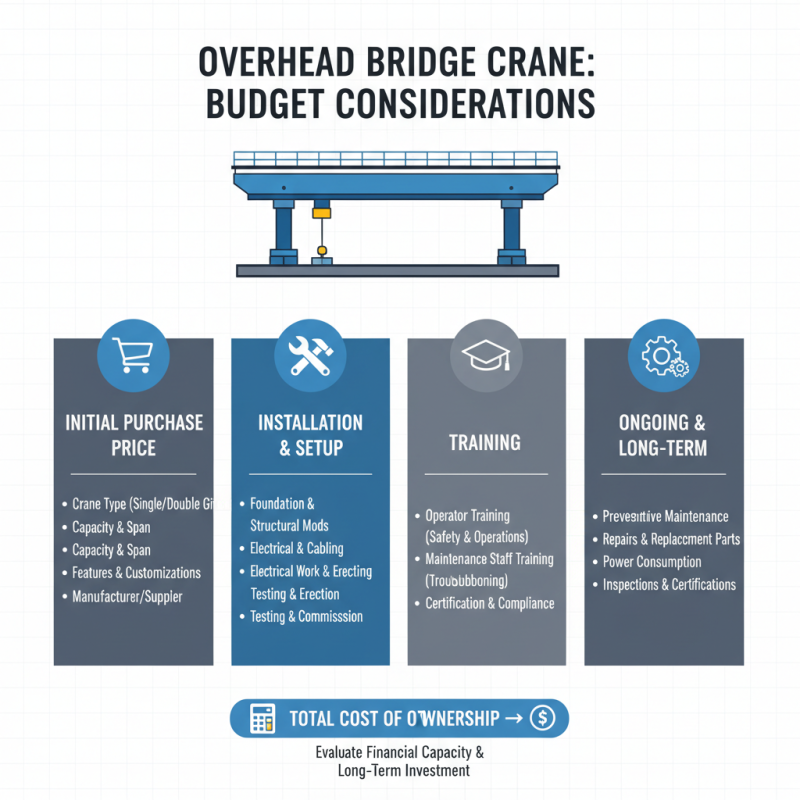

When selecting the right overhead bridge crane for your facility, budget considerations play a crucial role. It's essential to establish a clear budget that encompasses not only the initial purchase price of the crane but also installation, training, and ongoing maintenance costs. Depending on the type of crane you choose, these costs can vary significantly. Therefore, evaluating your financial capacity while understanding the long-term implications of your investment is crucial for making an informed decision.

Maintenance considerations are equally important in the selection process. A crane that requires frequent repairs or specialized service can quickly escalate operational costs. It's advisable to choose a crane with a good track record of reliability, as well as one that comes with straightforward maintenance protocols. Additionally, consider the availability of spare parts and trained technicians in your area, as this will affect the ease of maintenance and potential downtime.

Tips: Always conduct a thorough cost analysis, taking into account not just the purchase price but the lifetime costs associated with the crane. Additionally, invest in training for your staff to ensure they are equipped to handle routine maintenance and minor repairs, ultimately lowering the overhead costs. Regular maintenance schedules should be established to prolong the lifespan of the crane and maintain efficient operations.