Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

Selecting the right Overhead Bridge Crane can be challenging. Jon Matthews, a renowned expert in the lifting industry, once stated, “Choosing the right crane is crucial for safety and efficiency.” Each crane serves different business needs, so careful consideration is necessary.

An Overhead Bridge Crane will directly impact workflow and productivity. It's essential to assess your operational needs and facility layout. Consider the weight capacities and the types of loads you'll be lifting. Evaluating these factors can be the difference between seamless operations and costly errors.

Mistakes in crane selection can lead to accidents and financial loss. A mismatch in capacity or design can hinder your operations. Reflecting on your specific requirements is vital. Make informed choices, as an Overhead Bridge Crane is a long-term investment for your business.

When selecting an overhead bridge crane, understanding the types available is key. Common options include top-running and under-running cranes. Top-running cranes ride on the beams of the building structure. They are ideal for heavier loads. Under-running cranes, on the other hand, hang from the beams. They work well in areas with limited headroom.

Tips: Assess your workspace height. Consider load weight and size.

Another option is the gantry crane. This type provides mobility. It can be moved around the workspace. This flexibility is beneficial for varied projects. However, it may not be suitable for all environments.

Tips: Determine if constant repositioning suits your workflow. Evaluate if mobility can improve efficiency.

Choosing the right crane also means looking at functions. Some cranes are designed for fast operations. Others focus on precision movements. Match the crane's capabilities with your business needs. Prioritize safety features. Safety should not be overlooked even if costs rise.

Choosing the right overhead bridge crane hinges on evaluating load capacities. Before making a decision, assess your specific lifting requirements. Consider the weight of the items you will handle. Each crane has its limits. Exceeding these can lead to accidents or equipment damage.

Safety is paramount in crane operation. Ensure the crane can comfortably lift your maximum loads. This might involve some calculations or consultations with experts. Also, look at the frequency of use. A crane used daily needs a higher capacity than one used occasionally. It’s wise to slightly overestimate required capacities.

Efficiency is also impacted by load limits. If a crane struggles under heavy loads, productivity decreases. Slow lifting can frustrate workers and stall operations. Balance is key. A crane that is too powerful can be costly and inefficient for light tasks. Reflect on your needs carefully.

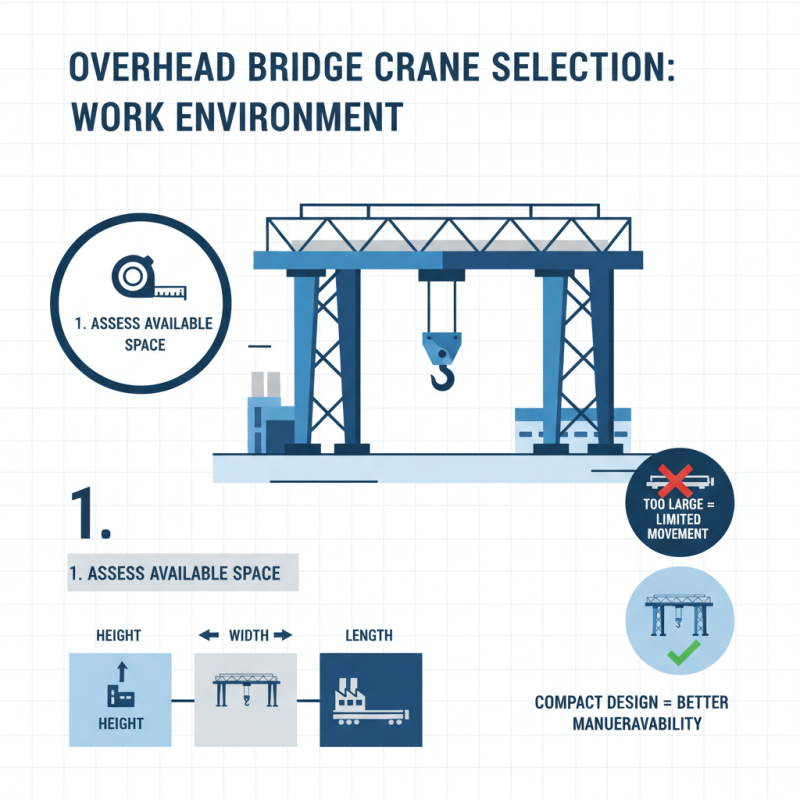

When selecting an overhead bridge crane, assessing your work environment is crucial. The first step is to evaluate the available space. Make sure to measure the height, width, and length of the area. A crane that is too large may limit movement and cause issues. A compact design could provide better maneuverability in tight spots.

Consider the types of materials handled in the facility. Heavy equipment may require a crane with a higher lifting capacity. Are there obstacles like beams or pipes? These can affect crane installation and operation. Additionally, understand how often the crane will be used. Frequent use demands a more robust solution, while occasional needs might allow for lighter models.

Don’t overlook environmental factors. Dusty or wet conditions can impact crane performance. Reflect on whether the crane will operate indoors or outdoors. Each environment brings unique challenges. Be willing to adjust your criteria based on these reflections. Balancing all these details can be tough, but it lays a solid foundation for your selection process.

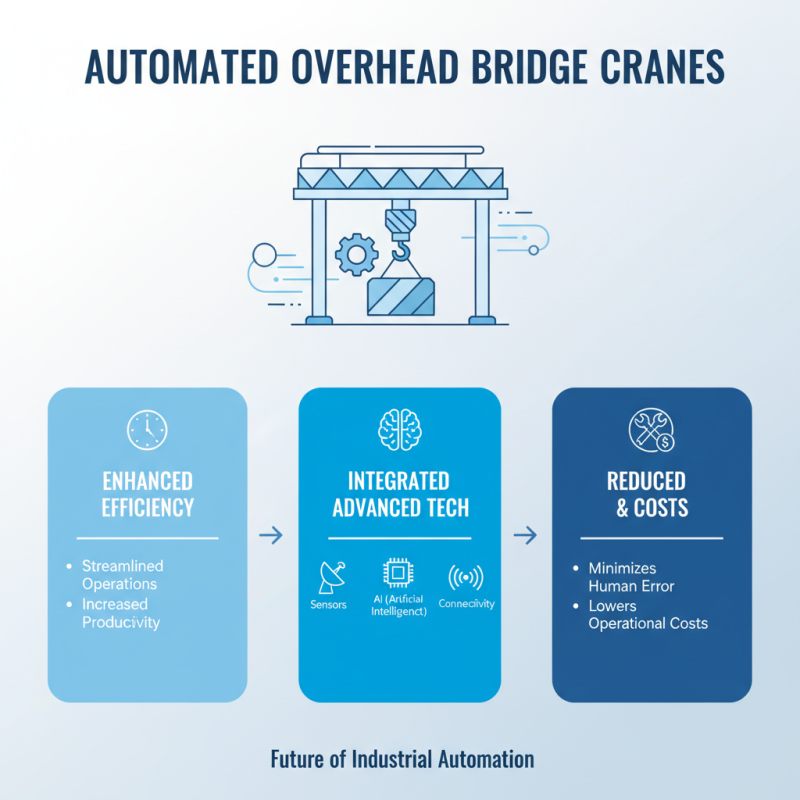

In today's rapidly evolving industrial landscape, automation plays a crucial role in enhancing efficiency and productivity. Modern overhead bridge cranes are now integrating advanced technologies such as sensors and AI. These features streamline operations and reduce the chances of human error, which can lead to costly mistakes.

Consider a facility where loads are frequently lifted and moved. An automated crane system can execute these tasks with precision and speed. Real-time data tracking allows operators to monitor loads, ensuring safety and compliance. Yet, not all businesses can adapt to this technology seamlessly. Staff training and adjustment periods might pose challenges.

However, investing in automation is not just about efficiency. It's also about long-term growth. Integrating modern crane technologies can provide valuable insights into operations. This may lead to smarter decisions. The risk is in overlooking the initial challenges while focusing too much on the benefits. Finding the right balance is essential for success.

When selecting an overhead bridge crane, budget considerations are paramount. A 2021 industry report revealed that 55% of businesses struggle with balancing initial costs and long-term investments. The purchase price of cranes can be significant, often ranging from $15,000 to over $100,000. However, this figure does not encompass the total cost of ownership, which includes maintenance, training, and operating expenses.

Investing in a crane that is expensive upfront might yield better long-term efficiency. According to data, cranes with advanced safety features and automation can reduce labor costs by 30%. Yet, many businesses opt for lower-cost models, tempted by immediate savings. This decision can lead to higher maintenance costs, impacting overall productivity. A deeper reflection on this choice could reveal that a more expensive crane, while initially daunting, may provide a more strategic advantage over time.

Consider how downtime affects your operations. For instance, about 20% of companies report productivity losses due to equipment failures. A more durable crane might have a higher price tag, but it can result in fewer disruptions. In the long run, evaluating the cost versus investment often leads to better decisions. Balancing budget constraints with potential savings is essential for making an informed choice.