Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

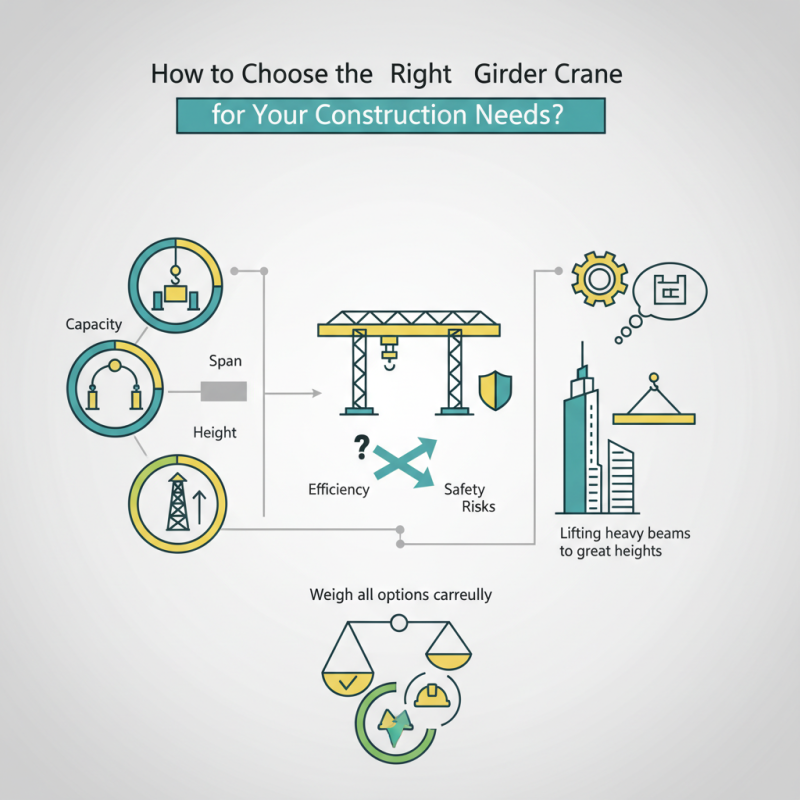

Choosing the right girder crane for your construction needs is crucial. A girder crane plays a key role in improving efficiency on job sites. With various options, selecting the best one can feel overwhelming.

Consider factors like capacity, span, and height. Each project has unique requirements. A wrong choice can lead to inefficiencies and safety risks. It often takes deep reflection on the specific tasks at hand.

Visualize scenarios where a girder crane can make a difference. For instance, lifting heavy beams to great heights requires the right specifications. Some cranes may fit your needs but lack the right power. It's essential to weigh all options carefully. By doing so, you can ensure optimal performance and safety on your construction projects.

When selecting a girder crane, understanding the types involved is crucial. There are two main categories: single girder and double girder cranes.

Single girder cranes are often lighter and more cost-effective. They are ideal for lighter lifting tasks. However, they have limitations in lift height and capacity. Reports indicate that these cranes typically handle loads up to 10 tons. They are suitable for warehouses and small construction sites.

Double girder cranes, on the other hand, offer greater strength and are capable of lifting heavier loads, often exceeding 20 tons. They provide better stability and more lifting height, making them suitable for large construction projects. According to industry studies, about 60% of large-scale operations benefit from this type. However, they come at a higher cost and may require more maintenance.

It's essential to evaluate the project scope before making a decision.

Ignoring the specific requirements may lead to operational inefficiencies. If a single girder crane is used for a heavy task, the results could be detrimental. Conversely, choosing an oversized crane for a light task leads to unnecessary expenses.

Balancing these factors is key to optimal performance and cost-effectiveness in construction projects.

Choosing the right girder crane involves understanding load capacity and weight limits. Each project has specific requirements. Knowing how much weight your crane can handle is crucial. If you underestimate these limits, it could lead to serious safety risks and project delays. Always consult the specifications carefully.

Calculating the total load includes the weight of the materials and any additional equipment. A miscalculation here can affect the crane's performance. For instance, if you need a crane for heavy steel beams, ensure it meets the required capacity. Adjustments may be needed for different load distributions.

Remember, different types of girder cranes have varied capacities. Analyzing your project’s demands is important. Overloading can lead to mechanical failure or accidents. Observe safety protocols and consider potential future needs. It’s wise to be cautious. Reflect on whether you've fully assessed what’s best for your construction goals.

When selecting a girder crane for your construction site, evaluating span and height is crucial. The span refers to the distance between supports, while height affects lift capability. Industry data suggests that a typical crane requires a span between 10 to 60 feet, depending on project scale. Taller cranes generally provide more clearance for materials.

Tips: Consider your site layout. If space is limited, opt for a compact design. This can significantly enhance efficiency.

Assessing your site’s height requirement is vital. The National Institute of Standards and Technology indicates that cranes must clear surrounding structures. Take note of any existing overhead obstacles. A detailed site survey can help identify these factors.

Tips: Measure heights once materials are on-site. This ensures you have the correct data for optimal crane selection.

Not considering proper span and height can lead to inefficiencies. An incorrect choice might result in unnecessary delays or increased costs. Always factor in future expansion. As project needs grow, a crane that offers flexibility becomes essential. Making a well-informed decision significantly impacts productivity and safety on your site.

When selecting a girder crane, safety features should be a primary focus. Cranes must comply with industry standards such as OSHA and ASME. According to a recent report from the American Crane and Hoist Association, 42% of crane accidents stem from improper operation. Ensuring safety features—like overload protection and emergency stops—can significantly reduce such risks.

Before making a choice, inspect the crane's qualifications. Look for features that enhance stability and operator visibility. The right crane design can prevent accidents on job sites. Moreover, regular maintenance is crucial. Neglecting this aspect often leads to failures that could be avoided with proactive measures.

Tip: Always conduct a thorough risk assessment before purchasing. It helps identify potential hazards specific to your construction site.

In the end, don't overlook operator training. Employees should understand the safety protocols related to the crane. The right training can further mitigate risks. As the saying goes, a neglected aspect can lead to unintended consequences.

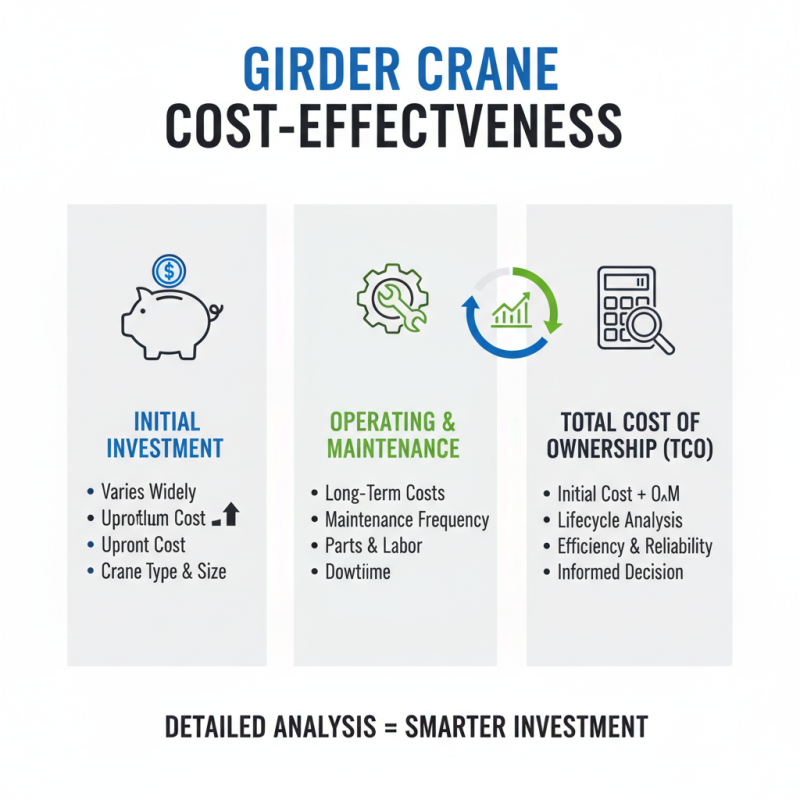

When selecting a girder crane, several factors influence cost-effectiveness. The initial investment can vary widely. While some options appear cheaper upfront, they may lead to higher maintenance costs over time. A detailed analysis is vital to understand the total cost of ownership.

Maintenance needs are another critical aspect. Simple designs may require less routine upkeep, but complex systems can lead to unexpected repairs. It’s essential to evaluate the availability of replacement parts and skilled labor for maintenance. For instance, if a crane has a unique part that requires a long lead time, downtime increases.

Operational efficiency should also be considered. An inefficient crane can lead to delays and additional labor costs. In some cases, investing in a more expensive model could yield savings in productivity and staff hours. Additionally, the training required for different models adds to the overall investment. It’s important to reflect on these factors to make an informed choice.