Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In the ever-evolving landscape of construction, selecting the right Eot Crane is pivotal for enhancing productivity and ensuring safety on job sites. According to a recent report by the Construction Equipment Market Research Institute, the global Eot Crane market is expected to witness significant growth, with an estimated CAGR of 6.3% from 2023 to 2028. This highlights the increasing reliance on advanced lifting solutions in modern construction settings, where efficiency and precision are paramount.

As industry expert Dr. Joseph Lin, a renowned specialist in crane technologies, aptly puts it, "The choice of an Eot Crane can vastly impact the operational efficiency of a construction project; therefore, understanding specific project requirements is essential." With innovations in design and technology, construction professionals must consider factors such as load capacity, span length, and environmental conditions when choosing an Eot Crane tailored to their unique needs. By carefully evaluating these aspects in 2025, stakeholders can greatly enhance operational workflows while simultaneously maintaining high safety standards on construction sites.

When selecting an EOT (Electric Overhead Traveling) crane for construction purposes in 2025, several critical factors come into play, significantly impacting efficiency and safety. The first consideration is the crane's load capacity. According to the Material Handling Industry (MHI), the average load capacity for projects has increased by about 15% over the past five years, reflecting a shift towards heavier construction materials. It’s essential to analyze the specific weight of materials that will be handled to ensure the EOT crane can accommodate these demands without compromising safety.

Another crucial factor is the span and lift height of the crane. The necessary dimensions largely depend on the construction site layout and the types of projects being undertaken. Recent industry reports indicate that companies are increasingly opting for cranes with adjustable spans and greater lift heights, which provide versatility in navigating complex construction environments. Additionally, advancements in technology, such as integrated load monitoring systems, have become standard features in modern EOT cranes, enhancing operational precision and reducing the risk of accidents.

Lastly, considering the power supply and environmental conditions is vital for optimal performance. An EOT crane should be compatible with existing electrical systems and designed to withstand the unique challenges posed by the construction site, such as extreme temperatures or limited space. The National Association of Manufacturers projects that by 2025, as construction sites become increasingly automated, the demand for EOT cranes with smart capabilities will rise, allowing for more efficient project execution and reduced operational downtime.

When selecting the right electric overhead traveling (EOT) crane for construction needs in 2025, understanding the various types available is crucial. EOT cranes are categorized into different types based on load capacity, span, and lifting height, each tailored to specific applications. According to a recent industry report by Research and Markets, the global crane market is projected to reach $40 billion by 2025, driven by infrastructural developments, especially in emerging regions. This growth underscores the importance of selecting the right type of EOT crane tailored to your project requirements.

The two primary types of EOT cranes are single girder and double girder cranes. Single girder cranes are typically lighter and more economical for loads up to 10 tons, making them suitable for smaller construction sites or warehouses. In contrast, double girder cranes can handle heavier loads and provide better height clearance, catering to larger construction projects where higher operational efficiency is required. A report from Allied Market Research reveals that the demand for double girder EOT cranes is expected to grow significantly, particularly in industries such as manufacturing and construction, where high load capacities are essential for productivity and safety.

Furthermore, advancements in automation and technology, such as smart control systems and enhanced safety features, are becoming increasingly important in selecting EOT cranes. A study by the International Journal of Advanced Manufacturing Technology highlights that cranes equipped with IoT (Internet of Things) capabilities can improve operational efficiency by up to 30%. As construction continues to evolve, choosing the right type of EOT crane, with considerations for load capacity, structural needs, and technological advancements, will be essential for successful project execution.

When selecting the appropriate Eot crane for your construction project, evaluating load capacity and specifications is crucial. Each project has its unique requirements based on the type of materials being lifted, the weight of the loads, and the operational environment. Start by determining the maximum weight your crane will need to handle. Consider factors such as safety margins, dynamic loads, and the frequency of use, as these will influence the overall design requirements of the crane.

In addition to load capacity, attention should be paid to the physical specifications of the crane, such as lift height, span, and reach. These dimensions will dictate how effectively the crane can maneuver within the workspace. Evaluating the technical specifications in relation to your specific site layout, equipment configuration, and workflow will help ensure operational efficiency. Remember, an ill-suited crane may lead to decreased productivity, increased wear and tear, and potential safety hazards on site. Hence, taking the time to thoroughly assess load capacities and specifications is essential for a successful construction operation.

When selecting the right EOT crane for your construction projects in 2025, understanding safety standards and compliance is crucial. Over the past few years, the construction industry has seen a shift towards stricter regulations to enhance workplace safety. According to a report by the Occupational Safety and Health Administration (OSHA), approximately 70% of crane-related accidents are attributed to operator error and equipment failure. This emphasizes the need for cranes that not only comply with existing safety standards but are also equipped with advanced safety features.

Compliance with standards such as the American National Standards Institute (ANSI) and the Crane Manufacturers Association of America (CMAA) ensures that the equipment you choose adheres to rigorous safety protocols. For instance, ANSI standards require periodic inspections of equipment to mitigate risks associated with wear and tear. Furthermore, the latest industry reports indicate that cranes with integrated safety technologies, such as load monitoring systems and anti-collision devices, significantly reduce the likelihood of accidents. In 2024, surveys revealed that nearly 45% of construction companies that adopted such technologies reported a substantial drop in incident rates, underscoring their importance in modern crane selection. Ensuring that your EOT crane meets these compliance standards not only safeguards your workers but also enhances operational efficiency.

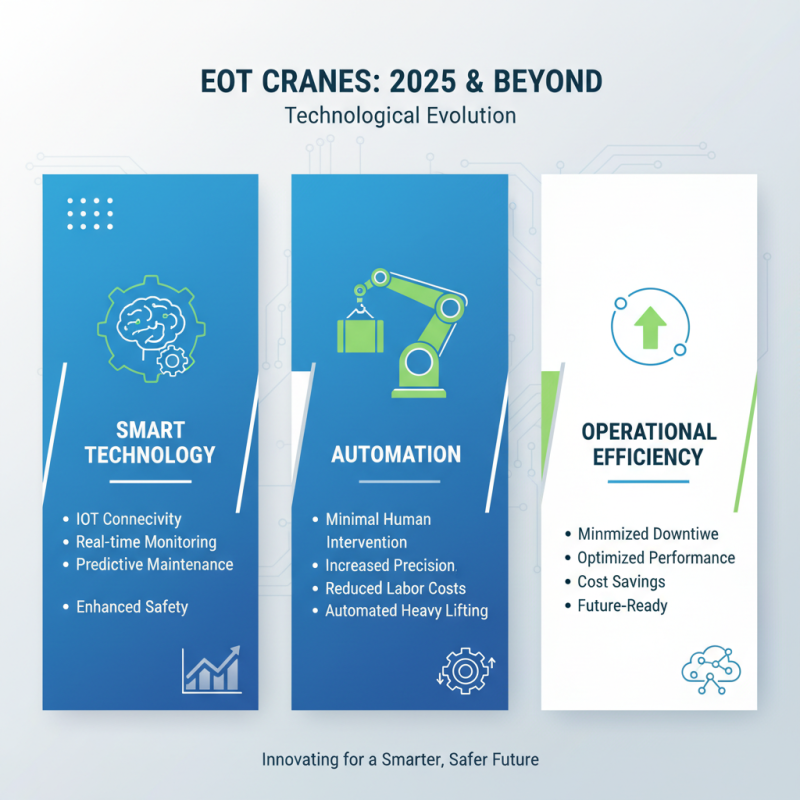

As we move toward 2025, the evolution of EOT (Electric Overhead Traveling) cranes is witnessing significant advancements in technology. One of the most notable trends is the integration of smart technology, which enhances operational efficiency and safety. Features such as IoT connectivity allow for real-time monitoring of crane performance, enabling predictive maintenance and minimizing downtime. Furthermore, advancements in automation are paving the way for cranes that can operate with minimal human intervention, reducing labor costs and increasing precision in heavy lifting tasks.

When selecting the right EOT crane for your construction needs, consider the emerging trends and technological features. Here are a few tips to guide your choice:

- **Prioritize Smart Features**: Look for cranes equipped with IoT sensors and automated control systems to improve efficiency and reduce operational risks.

- **Focus on Safety Enhancements**: Consider cranes with advanced safety measures, including overload detection, anti-collision systems, and operator training simulations.

- **Evaluate Energy Efficiency**: As sustainability becomes increasingly important, choose cranes designed for energy efficiency and reduced environmental impact, which can also result in lower operational costs.

Keeping these trends in mind will help you make a more informed decision when choosing the right EOT crane for your construction projects in the coming years.