Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

Choosing the right indoor crane can be challenging. Various factors impact the decision. Understanding these factors ensures you make the best choice.

Indoor cranes come in different types and sizes. Each type serves a specific purpose. You must think about your workspace and load requirements. Consider the layout of your facility and any obstacles present. Safety is paramount. Will your crane have safety features? Reflecting on these details is essential.

Many users overlook the importance of proper installation. This can lead to inefficiencies and accidents. Assessing your needs realistically is crucial. It might be easy to go for a powerful crane, but does it fit your space? Keep these questions in mind as you explore options. Your choice can greatly impact productivity and safety in the long run.

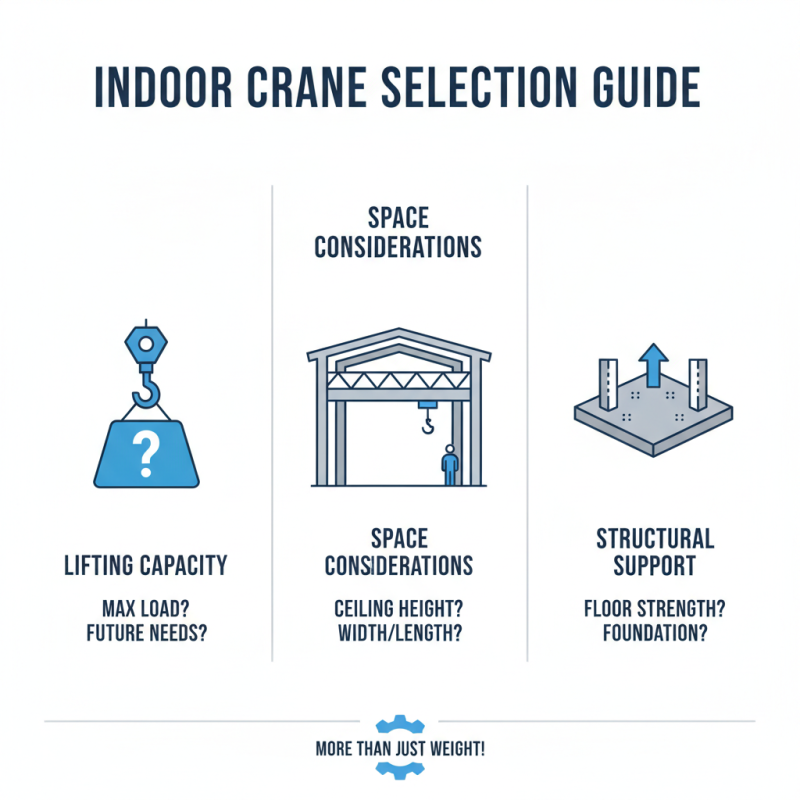

Choosing the right indoor crane can be challenging. Several factors come into play. It's not just about lifting capacity. You must also consider the space where the crane will operate. Does it have enough ceiling height? Is the floor level and strong enough to support heavy loads? These questions are crucial in making the right decision.

Another key factor is mobility. Some cranes are fixed, while others are portable. If your work requires moving the crane frequently, a portable model may be better suited. Think about your workflow and how often you will relocate the crane. Additionally, assess the ease of operation. Is the control system user-friendly? Complicated controls can lead to mistakes. A crane that is easy to operate can save time and reduce accidents.

Lastly, consider the safety features. Safety should never be compromised. Look for features like emergency stops and overload protection. While many cranes have these functions, not all are created equally. Reflect on your safety standards and ensure the crane meets them. It's not just about choosing a crane; it's about selecting one that fits your needs while prioritizing safety and efficiency.

When selecting an indoor crane, understanding the types and their specific applications is crucial. There are several types of indoor cranes, each designed for different tasks. Bridge cranes are prevalent in manufacturing. They can lift heavy loads and traverse large areas. Data shows that these cranes can enhance productivity by up to 25% in assembly lines.

Gantry cranes are versatile as well. They are often used in warehouses for moving materials. Their design allows movement across the floor area. A recent study indicates that gantry cranes reduce handling times by approximately 30%. Another option is the jib crane, ideal for lifting in small spaces. They provide a reach of 180 degrees, which is beneficial in tight environments. However, they are limited by their load capacity.

Despite their advantages, choosing the right crane can present challenges. Each facility has unique requirements. For example, ceiling height and load sizes vary significantly. Additionally, not every crane may suit your specific operations. Mistakenly selecting an inappropriate crane can lead to inefficiencies. Reflect on your space and needs carefully to avoid this common pitfall. Understanding the applications of different crane types is the first step in making an informed decision.

When selecting an indoor crane, weight capacity is a critical factor. You need to understand the maximum load the crane can handle. A common guideline across industries suggests that cranes should be rated for at least 20% more than the intended load. This extra margin ensures safety and accounts for dynamic forces during operation. According to a report by the Material Handling Industry of America, improperly rated cranes contribute to nearly 30% of workplace accidents.

Understanding your specific load requirements matters, too. Consider the load's size, shape, and how it will be lifted. Not all cranes are versatile enough for every load type. Some may excel in lifting heavy machinery, while others work well for lighter, bulkier items. Reports show that 50% of businesses overlooked these aspects, leading to equipment failures. Load dynamics can shift, causing slippage or accidents.

Also, think about attachment options and configurations. Do you need special hooks or slings? Many overseers underestimate these details, leading to setbacks. For instance, using an unsuitable hook can compromise safety. Assess your needs carefully and consult with experts. Balancing load capacity with specific operational requirements requires a detailed approach.

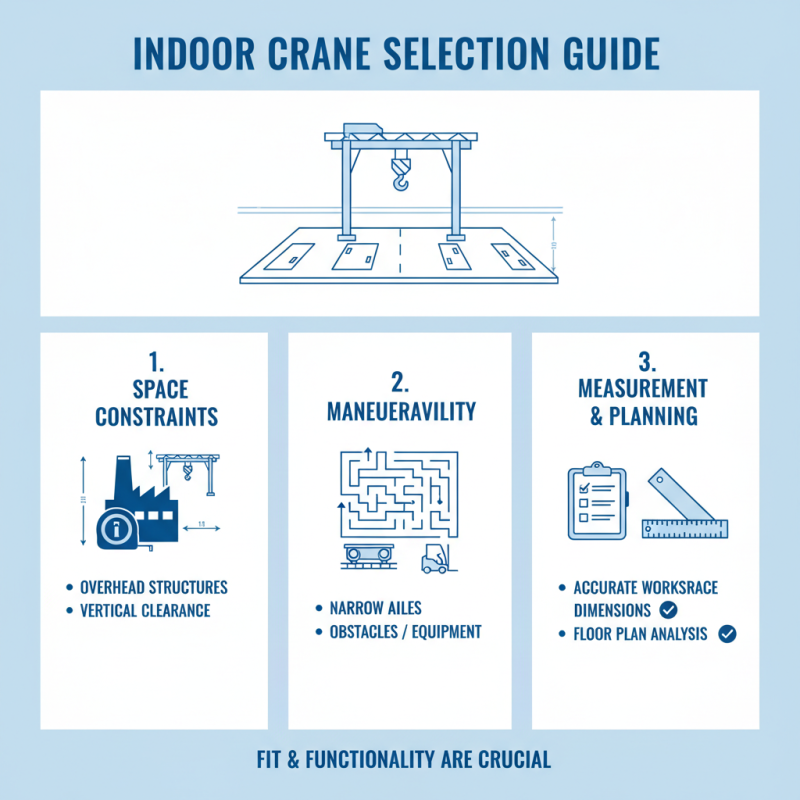

Choosing the right indoor crane involves careful consideration of space constraints and maneuverability. Indoor environments often have specific dimensions. A crane must fit without causing obstructions. Measure your workspace accurately. Note any overhead structures or narrow aisles. These factors will influence your crane selection.

Tips: Look for cranes with a compact design. They can navigate tight spaces more easily. Some models also have adjustable outriggers, which help maintain stability without excessive footprint.

Maneuverability is crucial. An ideal crane should allow smooth operation in confined areas. Consider the turning radius. Cranes with a smaller radius can work better in crowded rooms. Assess the ease of movement; operators should feel confident and safe.

Tips: Evaluate features like remote controls or ergonomic handles. These enhance control in busy settings. A crane that is tough to maneuver can lead to accidents or damage. Always prioritize your workspace’s layout before making a decision. Every space is unique; adapt the crane choice to fit your needs.

When selecting an indoor crane, safety features must be a top priority. Industry reports indicate that approximately 70% of crane accidents are due to improper use or equipment failure. Ensuring compliance with safety standards can significantly mitigate these risks. Check if the crane meets OSHA regulations or ANSI standards. These guidelines are designed to protect operators and those working nearby.

Evaluating safety features goes beyond just compliance. Look for cranes equipped with overload protection systems. Such systems can prevent tipping or structural failure. According to data, facilities that implement these features reduce incidents by up to 50%. Adequate training for operators is equally important. Studies show that a well-trained workforce can decrease accident rates dramatically.

Visual indicators can enhance safety as well. Cranes with clear load limits and emergency stop buttons allow for quick reactions in emergencies. However, users should also reflect on maintenance routines. Regular inspections can identify wear and tear, preventing potential failures. Remember, overlooking any of these aspects may lead to costly downtime and safety hazards.