Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

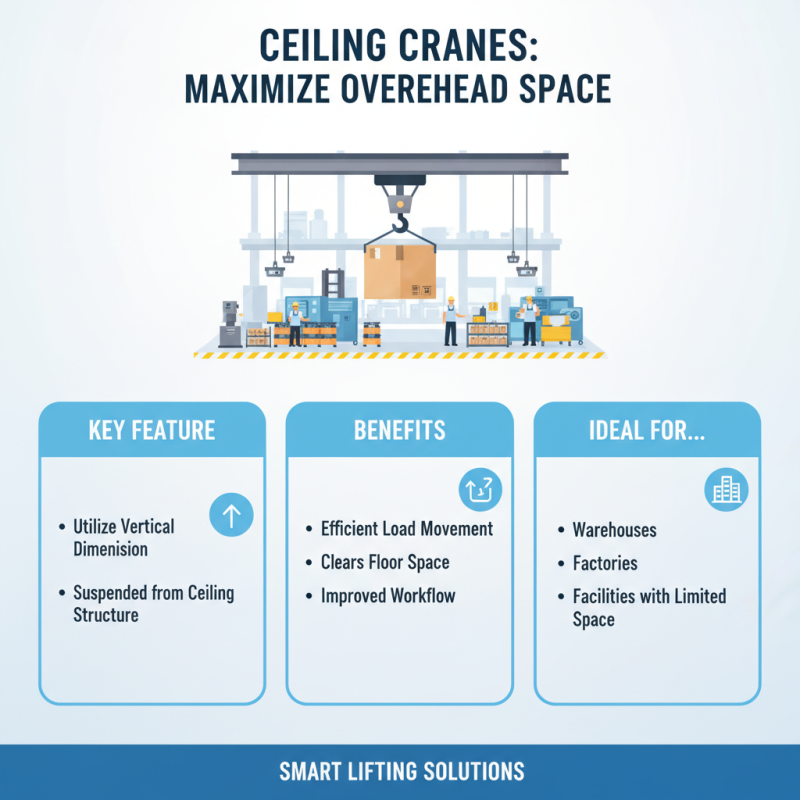

When considering various lifting solutions, a Ceiling Crane stands out as an efficient option. These cranes maximize vertical space, making them ideal for warehouses and workshops. Unlike traditional forklifts, they do not require floor space for maneuvering while moving heavy loads.

Choosing a Ceiling Crane can significantly improve workflow efficiency. The installation process, while straightforward, requires careful planning. Some users may struggle with understanding the load capacities and installation guidelines. It is essential to evaluate the specific needs before making a decision.

Investing in a Ceiling Crane enhances safety and productivity. However, not every facility may benefit equally from this choice. Assessing the layout and operations is critical. With careful consideration and planning, a Ceiling Crane could revolutionize your lifting needs.

Ceiling cranes offer distinct advantages in industrial settings. They save valuable floor space by utilizing overhead areas. This is crucial for warehouses where floor space is at a premium. With a ceiling crane, heavy loads can be moved effortlessly. Workers can lift materials without creating clutter below. This leads to a safer working environment.

Efficiency is another key benefit. Ceiling cranes speed up material handling processes. Items can be transported quickly from one spot to another. However, it’s vital to train employees properly. Incorrect use can lead to accidents. Regular maintenance is also necessary to ensure safety and functionality. Ignoring these aspects can create challenges for operations.

Flexibility is a hallmark of ceiling cranes. They can be designed to fit various industrial needs. Different lifting capacities are available, allowing for customized solutions. However, one must assess their specific requirements accurately. Overestimating the needed capacity can lead to unnecessary expenses. Each facility has unique demands, and understanding them is crucial before making a decision.

When considering lifting solutions, ceiling cranes stand out for their unique specifications and features. One key feature is their ability to maximize overhead space. Instead of relying on bulky ground equipment, ceiling cranes utilize the vertical dimension of a facility. This design allows for efficient movement of loads across large areas. Users find this particularly beneficial in warehouses or factories where floor space is limited.

Another important specification is the load capacity. Ceiling cranes can handle a variety of weights, depending on the model and requirements. Some systems may only lift a few hundred pounds, while others can manage several tons. The flexibility in design means that these cranes can be tailored to meet specific needs. However, this customization can lead to challenges. Determining the right capacity and dimensions can be tricky. Mistakes in this area may result in unsafe lifting practices.

Safety features are crucial. Many ceiling cranes include sensors and automatic shut-off systems. These elements help prevent overload situations, protecting both workers and equipment. Yet, not every facility fully implements these safety measures. Regular maintenance and operator training programs are essential. Without proper oversight, even the best crane systems can become unreliable. Understanding these aspects can significantly improve lifting operations while reducing risks.

Ceiling cranes play a vital role in various industries. They are designed to lift heavy loads efficiently. However, safety is a crucial consideration when using these cranes. Compliance with safety standards ensures the well-being of workers and the safety of materials. Knowing the regulations can help prevent accidents and injuries.

Many organizations overlook the maintenance of ceiling cranes. Regular inspections are essential for identifying potential hazards. Neglecting this aspect can lead to dangerous situations. Operators must be trained to understand these safety standards. They need to recognize red flags during their shifts. A small oversight can have serious consequences on the job site.

Adhering to safety standards is not always straightforward. Different industries may have varying requirements. This can create confusion. Companies must stay informed about these updates. Engaging with safety professionals regularly can promote a culture of safety. In this evolving landscape, continuous improvement is key.

Ceiling cranes offer significant cost-effectiveness for businesses. Unlike traditional lifting equipment, they utilize overhead space efficiently. This design can minimize the need for costly floor space. The initial investment might seem high, but they provide long-term savings on labor and time. By reducing the risk of damage to products, businesses can further enhance savings.

These cranes allow for effortless movement of heavy items. Workers can lift and transport loads with less manual effort. Reduced strain on employees leads to fewer injuries and lower healthcare costs. However, adapting to a new system may require training and adjustments. Transitioning your workflow can be challenging, yet the benefits often outweigh these hurdles.

Maintenance is crucial for maximizing the lifespan of ceiling cranes. Regular check-ups help avoid unexpected breakdowns and costly repairs. An initial oversight might lead to larger issues later. Being proactive in maintenance reflects a keen approach to long-term savings. Balancing costs and efficiency demands thoughtful decision-making and reflection on current practices.

| Feature | Ceiling Crane | Traditional Lifting Methods |

|---|---|---|

| Initial Investment | Moderate | Low |

| Maintenance Costs | Low | High |

| Labor Efficiency | High | Medium |

| Durability | High | Variable |

| Space Utilization | Excellent | Poor |

| Flexibility | High | Limited |

In manufacturing, ceiling cranes have transformed workflows. For example, an automotive plant adopted a ceiling crane system to streamline assembly. They reduced downtime significantly. Workers no longer struggled with heavy components. The crane moved parts effortlessly overhead, freeing up floor space.

In another case, a warehouse faced challenges with tall shelves. They implemented ceiling cranes to lift goods from high racks. Employees found it safer and faster to operate. However, initial training gaps led to some accidents. Reflecting on these events, they adjusted training programs and improved safety protocols.

In construction, a ceiling crane played a critical role in lifting materials to high-rise buildings. The efficiency boost was clear. Yet, coordination between workers still needed attention. Miscommunication resulted in a few near-misses. A post-project review highlighted the importance of clear signals and teamwork. With these lessons, they refined their operational strategy for future projects.