Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In the realm of material handling, efficiency is paramount, and selecting the appropriate equipment can significantly enhance operational productivity. Among various lifting solutions, the ceiling crane stands out as a versatile and effective option for moving heavy loads within facilities. With its design that utilizes overhead space, the ceiling crane helps to minimize floor space consumption while providing exceptional maneuverability.

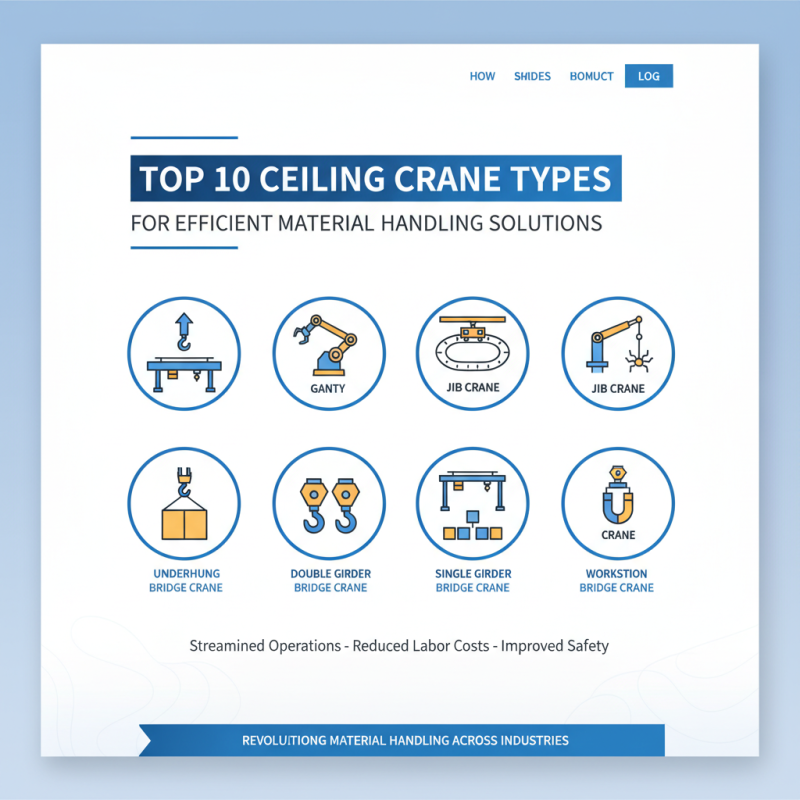

This article will explore the top 10 types of ceiling cranes that can revolutionize material handling processes across various industries. Each type offers unique features and capabilities tailored to meet specific operational needs, ranging from light-duty tasks to handling bulky, heavy components. By understanding the advantages and applications of different ceiling crane types, businesses can make informed decisions that lead to streamlined operations, reduced labor costs, and improved safety standards. Join us as we delve into the diverse world of ceiling cranes and their impact on efficient material handling solutions.

Ceiling cranes play a crucial role in material handling applications across various industries. Their design allows for efficient movement of heavy loads within a designated space, making them an ideal solution for warehouses, factories, and industrial sites. Different types of ceiling cranes, such as gantry cranes, monorail systems, and jib cranes, are available to accommodate specific handling needs. These cranes can typically be installed on existing building structures, maximizing available overhead space and minimizing floor clutter, which is essential for improving workflow and safety in any material handling environment.

One of the key advantages of ceiling cranes is their ability to facilitate smooth operations with minimal personnel required. Automation and remote control options further enhance their effectiveness, allowing for precise movements and load handling. Additionally, the diversity in design and functionality enables these cranes to be tailored to various tasks, from lifting large machinery components to moving bulk materials. By integrating the right type of ceiling crane into a material handling system, businesses can achieve increased productivity, reduced downtime, and enhanced overall efficiency.

When choosing a ceiling crane type for material handling, several key features should guide your decision to ensure optimal efficiency and safety. First, load capacity is paramount; it determines the maximum weight a crane can safely lift. According to a report from the Material Handling Industry of America, selecting a crane with a capacity that exceeds your highest anticipated load by at least 25% can prevent structural stress and enhance safety.

Another important feature is the span of the crane, which refers to the distance between the supporting structures. A crane with a wider span can accommodate more extensive operations and less obstructed movement, crucial in busy industrial environments. Additionally, consider the height underneath the crane; ensuring ample vertical space allows for easier loading and unloading processes. Ergonomics and ease of operation are also critical, with advanced controls and automation features increasing productivity. A study published in the Journal of Safety Research highlighted that automated systems can lead to a 30% increase in efficiency while reducing operator fatigue.

Lastly, the material and build of the crane influence its durability and maintenance needs. Steel structures, though heavier, are generally more resilient than lighter materials. Regularly scheduled maintenance, as reported in industry standards, can extend the operational life of the crane significantly, making it a wise investment in the long term. By weighing these factors, organizations can select the most effective ceiling crane type tailored to their specific material handling requirements.

Ceiling cranes, also known as overhead cranes, are vital tools in industrial settings, offering numerous advantages for material handling. One of the primary benefits of using ceiling cranes is their ability to maximize floor space. By utilizing vertical space, these cranes allow for the unhindered movement of materials while keeping the ground area clear for other operations. This enhancement in space management can lead to improved workflow and efficiency in busy industrial environments, facilitating easier access to materials and reducing the time spent transporting goods.

Another significant advantage of ceiling cranes is their capacity to handle heavy loads with ease and precision. Designed to lift and maneuver heavy materials, these cranes reduce the physical strain on workers and minimize the risk of workplace injuries associated with manual handling. Additionally, ceiling cranes can be equipped with advanced controls and safety features, ensuring that even the most complex lifting tasks can be performed safely and effectively. This combination of safety and efficiency contributes to a more productive work environment, ultimately leading to better operational outcomes in industries ranging from manufacturing to construction.

Operating ceiling cranes requires careful attention to safety considerations to ensure both the well-being of operators and the integrity of the materials being handled. One of the primary safety measures is proper training. Operators must be thoroughly educated on the operational guidelines, safe load limits, and emergency procedures. It's essential that all personnel understand the importance of adhering to these protocols to minimize risks of accidents in the workplace.

Tips: Regular safety drills can enhance operator readiness and response in real scenarios. Additionally, ensure that all operators are familiar with the specifics of the ceiling crane they will be using, including its controls and features.

Another vital aspect of safety involves routine maintenance and inspections. Regular checks can help identify potential issues before they become hazardous. Operators should inspect components such as hooks, cables, and controls at the start of each shift and report any irregularities immediately. Maintaining clear communication among team members during operations further enhances safety.

Tips: Implement a checklist for daily inspections and encourage a culture of accountability where team members actively report concerns. Moreover, visual signals can help coordinate movements and prevent mishaps during crane operation.

Ceiling cranes are essential for efficient material handling in various industries, but their effectiveness largely depends on proper maintenance. To ensure optimal performance, regular inspections and maintenance tasks are crucial. According to a report by the American Society of Mechanical Engineers, approximately 66% of crane-related incidents arise from improper maintenance and inspections. This statistic highlights the importance of developing a robust maintenance schedule to prolong the life and efficiency of your ceiling crane.

One critical aspect of maintenance is lubrication. Regularly lubricating moving parts can prevent wear and tear, which is vital for keeping your crane operational. Industry studies suggest that implementing a lubrication schedule can increase equipment lifespan by 20%. Additionally, checking and tightening loose bolts and connections can prevent significant operational hazards, as loose components can lead to equipment failure.

Another essential tip is to monitor the load capacity of your ceiling crane. Exceeding the specified load limits can cause excessive strain, leading to mechanical failure and safety risks. According to OSHA regulations, adhering to load specifications can minimize the risks of accidents and ensure compliance with safety standards. Training operators on the proper use of cranes and load management is also a fundamental part of maintenance, ensuring that everyone involved understands the importance of following best practices.

This bar chart illustrates the load capacity of various types of ceiling cranes used in material handling solutions. Understanding the load limits for each crane type is essential for optimal performance and safety in operations.