Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In the industrial sector, a Bridge Crane is an essential piece of equipment designed for heavy lifting and material handling. According to a report from MarketsandMarkets, the global crane market is projected to reach $45 billion by 2025. This growth is driven by increasing construction and manufacturing activities worldwide. Understanding how a Bridge Crane operates is crucial for efficiency in these industries.

Industry expert John Smith, a senior engineer at CraneTech, states, "Effective use of Bridge Cranes can significantly enhance productivity and safety on job sites." Bridge Cranes utilize a horizontal beam that moves along two parallel runways. They lift loads vertically, providing unmatched versatility. However, dependence on a single crane can lead to challenges, including potential overloading or miscalculations.

Despite their importance, improper operation of Bridge Cranes can lead to accidents and downtime. Worker training is often overlooked, which can be a critical factor in successful operations. Investing in proper education may minimize risks and maximize efficiency. Understanding these factors surrounding Bridge Cranes remains essential for everyone in the industry.

A bridge crane is an important tool in various industrial applications. It consists of a horizontal beam that moves along a set of rails. This design allows for the lifting and moving of heavy items across a wide area. Many factories use bridge cranes for material handling. According to a report by Market Research Future, the global overhead crane market is projected to reach $4 billion by 2025. This figure highlights the increasing reliance on such equipment.

Bridge cranes are capable of lifting loads that exceed several tons. They usually come equipped with electric hoists, which add precision to the lifting process. A significant challenge in using bridge cranes involves ensuring proper maintenance. Poor upkeep can lead to failures, causing potential safety hazards. Reports from the Occupational Safety and Health Administration indicate that improper handling incidents are a significant concern in many facilities.

The safety record for bridge cranes is not perfect. Many accidents occur due to operator error or mechanical failure. Regular training and inspections are necessary to mitigate these risks. In one survey, 30% of operators reported a lack of training before using the equipment. This gap in knowledge can lead to mistakes. Therefore, ongoing education and preventive maintenance are crucial for optimal performance in bridge crane operations.

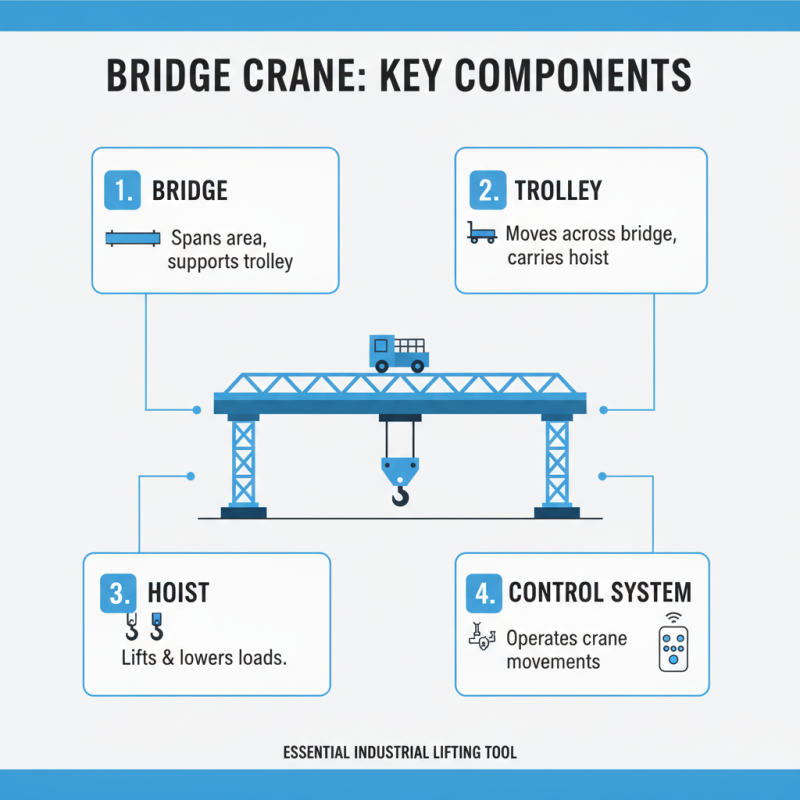

Bridge cranes are essential tools in various industries. Their design includes several key components, each with vital functions. The main parts are the bridge, trolley, hoist, and control system.

The bridge extends across the workspace. It allows for seamless movement of materials. Generally, professionals recommend bridge cranes for lifting heavy loads, often exceeding several tons. The trolley moves along the bridge. It carries the hoist, which does the actual lifting. This setup provides efficiency. It enables vertical and horizontal movement, which is crucial for warehouse operations.

Tips: Regular maintenance is essential. Inspect all components periodically. Look for wear and tear. Minor issues can lead to major setbacks.

The control system is user-friendly. It can be manual or automated. Automation can improve safety and productivity. However, improper setup may hinder performance. Training staff on the system is critical. Operators must understand each function well to avoid accidents. Understanding the intricacies of each component helps in optimizing crane operations.

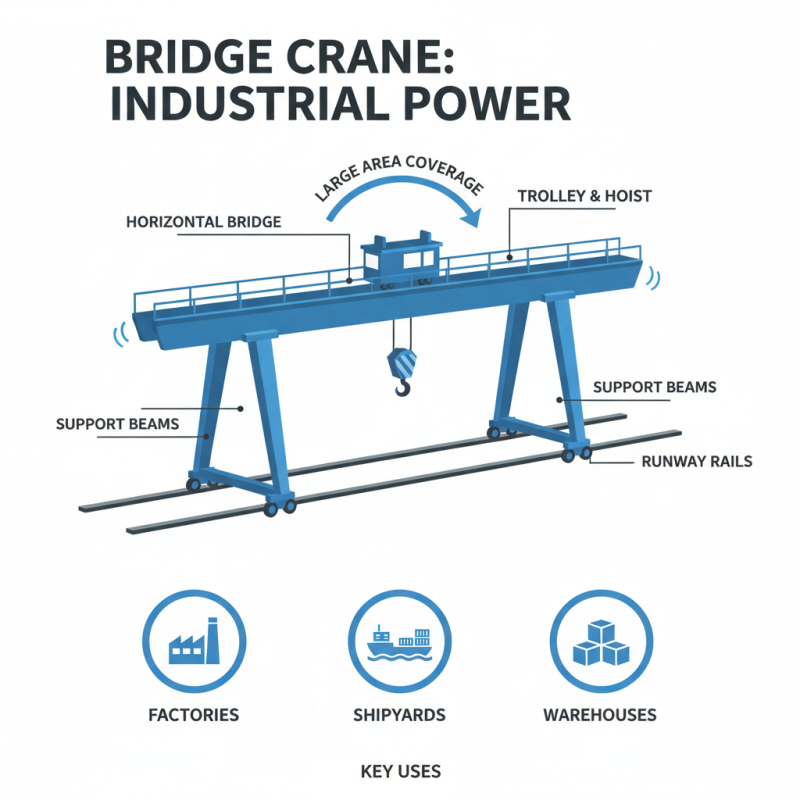

A bridge crane is a vital piece of industrial equipment. Its structure includes a horizontal bridge supported by two or more beams. The crane moves along a rail system. This setup allows it to cover large areas. It’s commonly used in factories, shipyards, and warehouses.

The operation of a bridge crane is driven by various mechanisms and controls. Electric motors typically power the movement along the rails. Most cranes feature a hoist unit that lifts and lowers cargo. Reports indicate that the global crane market reached approximately $45 billion in 2020, highlighting the demand for efficient lifting solutions. Remote controls and operator panels allow for precise maneuvering. However, operators must undergo proper training to avoid accidents.

Some bridge cranes lack integrated safety features, posing risks. Regular maintenance is crucial to ensure their longevity and reliability. Inspections should not be overlooked, as wear and tear can lead to failures. A study showed that 10% of crane incidents are due to inadequate inspections. So, understanding both the mechanisms and maintenance requirements is essential for safe operation.

Bridge cranes are widely used in various industries. They excel at lifting heavy loads and enhancing efficiency. In manufacturing, these cranes transport materials between production lines. They are vital in assembly processes, helping manufacturers keep pace with demand.

In the construction sector, bridge cranes move materials to different heights and locations. This aids in reducing manual labor and improving safety. Warehouse operations also benefit from bridge cranes. They enable quick loading and unloading of goods, streamlining logistics.

Tips: Always ensure operators are well-trained. Regular maintenance checks can prevent accidents. Pay attention to the load limit to ensure safety.

Bridge cranes find applications in shipping ports too. They assist in loading containers onto ships. This is crucial for keeping supply chains running smoothly. Yet, every facility has unique needs. A bridge crane may not fit every layout perfectly. Understanding these nuances is key to effective use.

Safety is a top priority when operating bridge cranes. Regular inspections are essential. Personnel should check for wear and tear on cables, hooks, and controls. Neglecting these checks can lead to accidents. Operator training plays a critical role. Proper understanding of the crane’s controls can prevent mishaps. Safety gear must be worn at all times. A helmet, gloves, and safety shoes are necessary. These measures may seem tedious, but they save lives.

Maintenance should follow a strict schedule. Cleaning is not just about appearance; it prevents rust and damage. Lubricating moving parts helps avoid mechanical failures. Parts that fail can lead to hefty repairs. Operators should keep a maintenance log. Documenting issues can reveal patterns that need attention. Sometimes, simple fixes can prevent larger problems. A proactive approach to maintenance can extend the crane's lifespan.

Even with strict safety measures, human error still exists. The environment can be unpredictable. Operators should be aware of their surroundings. Other workers may not notice the crane's movements. Communication is key. Using signals can help prevent accidents. Regular safety drills can keep everyone prepared. Promoting a safety culture encourages vigilance. Every worker plays a part in ensuring safer operations. Letting complacency slip in can have serious consequences.