Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

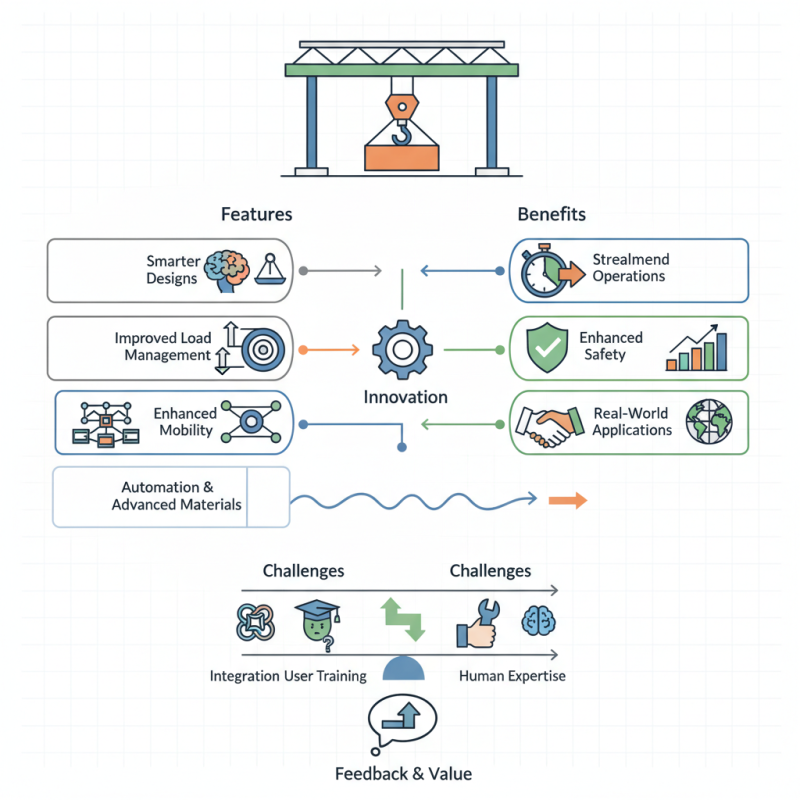

The Overhead Gantry Crane industry is evolving rapidly. In 2026, innovations promise to enhance efficiency and safety. John Smith, a renowned expert in crane technology, states, "The future of Overhead Gantry Cranes lies in smarter designs." His insights reflect the industry's shift toward automation and advanced materials.

New features will include improved load management systems and enhanced mobility. Users will benefit from streamlined operations. However, not every advancement will be flawless. Challenges with integration and user training may arise. The balance between new technology and human expertise remains critical.

As manufacturers innovate, the benefits must align with real-world applications. Understanding the practical uses of an Overhead Gantry Crane will drive its success. The industry must remain flexible and open to feedback, ensuring every feature adds genuine value.

In 2026, the design of overhead gantry cranes has evolved significantly. These cranes are now equipped with advanced features that enhance efficiency and safety. A notable feature is the use of AI-driven load monitoring systems. This technology allows real-time tracking of load weights, preventing overload and reducing accidents.

Another key innovation is the adoption of lightweight materials in crane construction. This has led to a decrease in energy consumption by up to 30%, according to recent industry reports. Operators can benefit from an improved operational speed as well. Enhanced lifting speeds contribute to increased productivity on job sites. Many companies report that faster cycle times lead to a noticeable boost in overall output.

However, challenges still exist. Some users find it difficult to adapt to new systems. Training sessions can be time-consuming and costly. Additionally, with more complex machinery, maintenance issues have emerged, leading to unexpected downtime. Striking the right balance between advanced features and user-friendliness remains essential for the future of overhead gantry cranes.

This chart illustrates the key features of overhead gantry cranes in 2026 based on their importance rating. Load capacity and safety features are the top priorities for users, while the control system and lift speed are also significant but less critical.

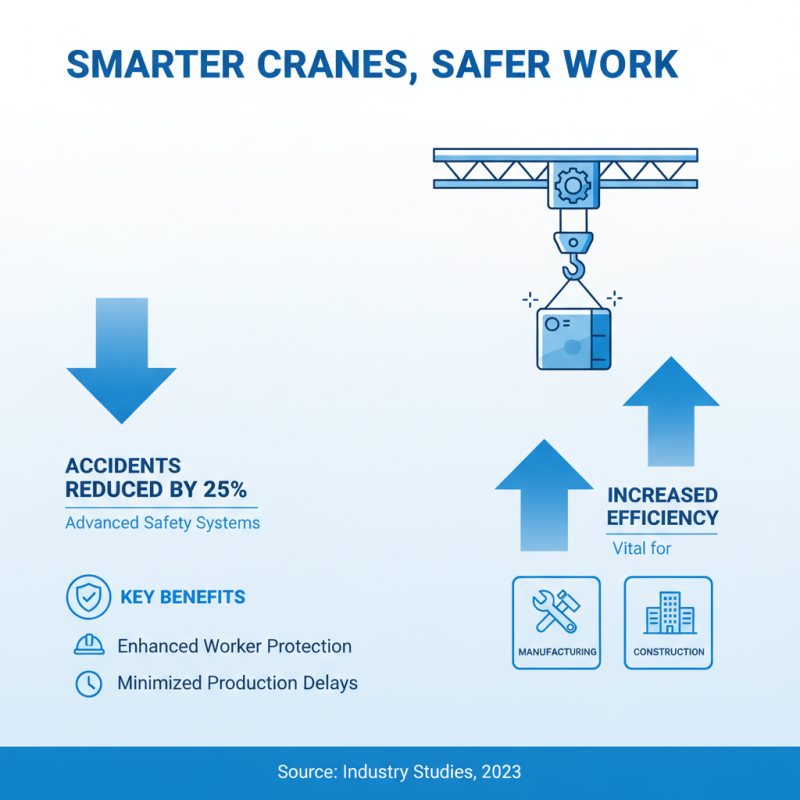

Overhead gantry cranes are crucial in various industries, particularly in construction and manufacturing. Advanced safety systems significantly enhance the operation of these cranes. A safety system can reduce accidents by as much as 25%, according to recent studies. This reduction in risks is vital, as workplace injuries can slow production.

One notable benefit of these safety features is the implementation of load monitoring systems. They can detect overloads and prevent potential failures. This technology ensures that workers remain secure, reducing injury and increasing trust in the machinery. Furthermore, emergency stop mechanisms are essential. They allow operators to halt operations instantly in case of a malfunction. Such systems provide peace of mind.

However, not all safety systems are foolproof. Regular maintenance and training are necessary to keep these safety features operational. A survey revealed that 30% of accidents occur due to human error, emphasizing the need for continuous education. While technology can help, human factors cannot be ignored. Investing time in training is as crucial as investing in equipment. These systems should evolve alongside the workforce, ensuring safety remains a priority in all crane operations.

The features of the 2026 top overhead gantry cranes reflect innovative technologies that significantly enhance efficiency. Many models now come equipped with advanced automation systems. These systems reduce the need for manual operation, increasing safety and productivity. Smart sensors monitor weight and load distribution in real-time, preventing accidents.

Tips: Regularly inspect the sensors. A small malfunction can affect safety and efficiency.

Remote control capabilities are also improving. Operators can maneuver cranes from a distance, providing flexibility in various work environments. This technology allows for better visibility and decision-making during operations. However, reliance on remote systems requires robust training. Operators must be familiar with potential technical issues.

Tips: Conduct regular training sessions. Even skilled operators can overlook new features.

Energy efficiency is another critical aspect. Many cranes now use hybrid power systems that reduce fuel consumption. While these advancements are advantageous, they may require upfront investment. These changes could lead to longer-term savings and a smaller carbon footprint. Balancing initial costs against future benefits is crucial for decision-makers.

When comparing different overhead gantry crane models, key features emerge. The

lifting capacity is a primary consideration. Many models offer capacities ranging from a few tons to over

100 tons. According to industry reports, cranes with higher capacities tend to be more robust.

However, their increased weight can limit mobility. Choosing the right model often requires balancing capacity and flexibility.

Another significant aspect is the span of the crane. Models vary widely in their spans, affecting their

operational reach. Some cranes can span up to 80 feet, while others may only reach

20 feet. A larger span allows more coverage within a facility. However, it may complicate installation

and require additional support structures. Reports suggest that more expansive models can sometimes lead to increased costs and maintenance challenges.

Safety features are also critical in selection. Many cranes

include limit switches, emergency stops, and anti-collision systems. However, some budget models may lack these essential safety measures.

This can lead to operational risks. A report indicated that nearly 40% of workplace accidents are

linked to equipment failures. Thus, investing in reliable safety features proves essential for avoiding hazards.

Selecting the right overhead gantry crane necessitates careful analysis of these factors to ensure operational efficiency and safety.

Overhead gantry cranes play a crucial role in various industries. They lift heavy loads with ease, making them invaluable in construction sites, warehouses, and manufacturing plants. These cranes can navigate large areas, enhancing workflow efficiency. Many sectors benefit from their flexibility and strength.

In manufacturing, overhead gantry cranes streamline production lines. They help in assembly processes, reducing manual labor drastically. In construction, these cranes hoist materials to great heights. This capability allows workers to focus on tasks without worrying about lifting heavy items. In warehouses, they optimize storage and retrieval procedures, thus maximizing space.

Tip: Ensure you assess the weight capacity of the gantry crane you choose. It's vital to operate within safe limits.

In the shipping industry, overhead gantry cranes facilitate container handling. They swiftly load and unload cargo, saving time and labor. However, improper usage may cause accidents or damage to goods. Operators need solid training and strict adherence to safety protocols.

Tip: Regular maintenance is essential to keep overhead gantry cranes in top working condition. Inspection routines can prevent unexpected breakdowns.

| Feature | Benefit | Application |

|---|---|---|

| High Load Capacity | Ability to lift heavy loads safely and efficiently | Manufacturing, Construction |

| Adjustable Height | Versatility for different types of operations | Warehousing, Logistics |

| Remote Control Operation | Enhanced safety and precision during lifting | Shipping, Ports |

| Durable Construction | Longevity and reduced maintenance costs | Mining, Heavy Industries |

| Modular Design | Easier upgrades and customization | Construction, Power Plants |

| Energy Efficiency | Reduced operational costs and environmental impact | Manufacturing, Distribution Centers |