Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

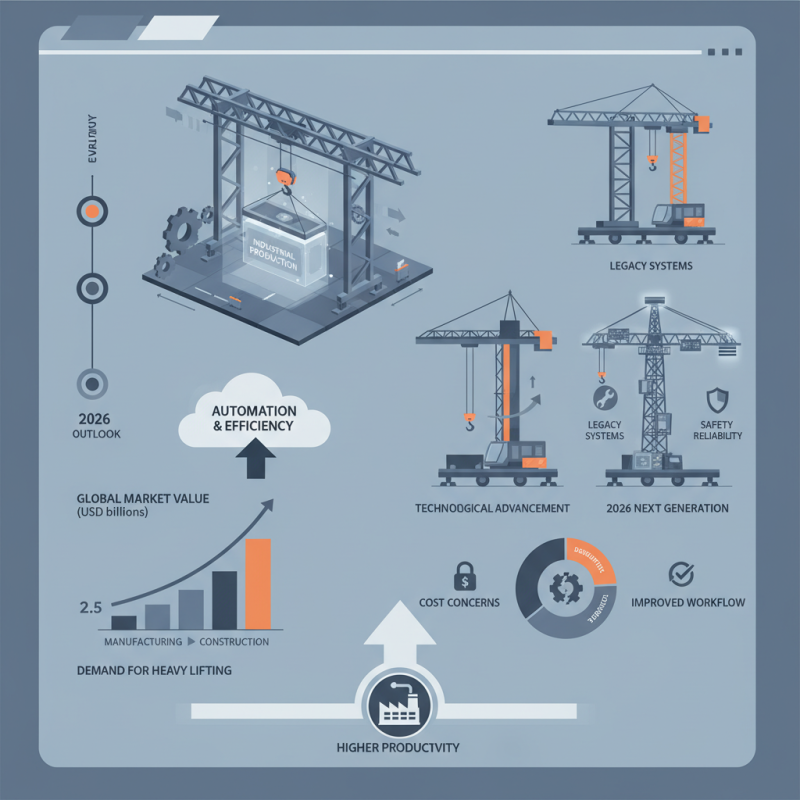

The global industrial landscape is evolving, with a noticeable shift toward automation and efficiency. Bridge cranes play a crucial role in this transformation. According to a recent report by MarketsandMarkets, the bridge crane market is projected to reach $3.3 billion by 2026, driven by increased demand for heavy lifting solutions in manufacturing and construction sectors.

Bridge cranes are known for their versatility and strength. They can lift heavy loads safely. However, many industries still struggle with outdated models. This presents an opportunity for manufacturers to innovate. Embracing advanced technology in bridge crane design can lead to enhanced performance and safety standards.

Despite the potential benefits, some companies remain hesitant to make upgrades. Concerns about costs and disruptions often hold them back. Yet, investing in modern bridge cranes can dramatically improve workflow and reduce operational risks. As industries aim for higher productivity, selecting the best models becomes critical. The 2026 best bridge crane models will likely set new benchmarks in safety, efficiency, and reliability.

Bridge cranes play a vital role in various industrial settings. They are designed to lift heavy loads efficiently and safely. These cranes are commonly used in factories, warehouses, and construction sites. They can be fitted with various attachments, such as hooks, grabs, or magnets, depending on the materials being handled.

In operations, the effectiveness of a bridge crane relies on its design and capacity. Standard models can handle loads from a few tons to over a hundred tons. However, choosing the right model can be challenging. Industries often face dilemmas regarding specifications and safety features. Each application presents unique challenges that may not align perfectly with available options.

Maintenance of these cranes is essential for safety and efficiency. Neglecting regular checks can lead to accidents or equipment failures. Many workers may overlook these practices, which is concerning. The balance between efficiency and safety is delicate. It's crucial to address these factors to enhance overall productivity in industrial applications.

When selecting bridge crane models for industrial applications, several key features deserve careful consideration. Load capacity is one of the primary factors. Most industrial cranes have a capacity ranging from 1 ton to over 300 tons. A recent industry report highlighted that 70% of facilities choose cranes based on the specific load they intend to handle. Thus, it’s important to accurately assess your operational needs.

Another essential feature is the span of the crane. The width between rails can affect operations significantly. A wider span allows for greater reach, but it may require more space for installation. According to industry data, over 60% of operational delays are linked to poorly configured spans. This highlights the need for precise measurements and planning.

Safety features are also critical. Modern cranes must include emergency stop buttons, overload protection, and anti-collision systems. Reports indicate that nearly 40% of workplace accidents are related to crane operations. This statistic emphasizes the importance of prioritizing safety in your selection process. Balancing these features with your budget is a common challenge. Too often, companies overlook the long-term value of investing in well-equipped cranes.

This chart illustrates the load capacities of top bridge crane models for industrial applications in 2026. It highlights the different models and their respective capabilities, providing a clear comparison for selection.

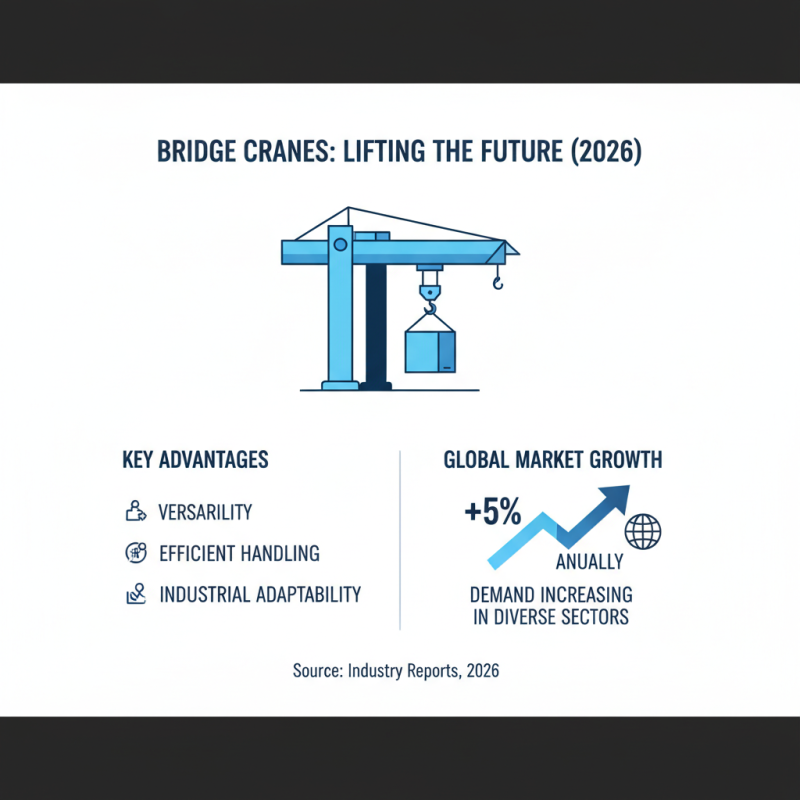

As industries continue to evolve, the demand for efficient lifting solutions rises. In 2026, bridge cranes stand out as vital tools in various sectors. These cranes offer excellent versatility and handling capabilities. According to recent industry reports, the global market for bridge cranes is projected to grow by over 5% annually, reflecting their increasing importance.

Among the top five models this year, several factors matter most. Load capacity is crucial. Many models can handle up to 100 tons. This versatility makes them suitable for manufacturing, shipping, and construction. Operators must consider operational costs as well. Some units consume more energy than anticipated. This can affect overall efficiency and budget.

Furthermore, safety features play a pivotal role. Monitoring systems must be accurate and responsive. Inadequate safety protocols can lead to severe accidents. The challenge lies in ensuring that all models meet stringent regulations while remaining budget-friendly. As technology advances, manufacturers are exploring smart features for better performance. This pushes the industry closer to a more efficient future.

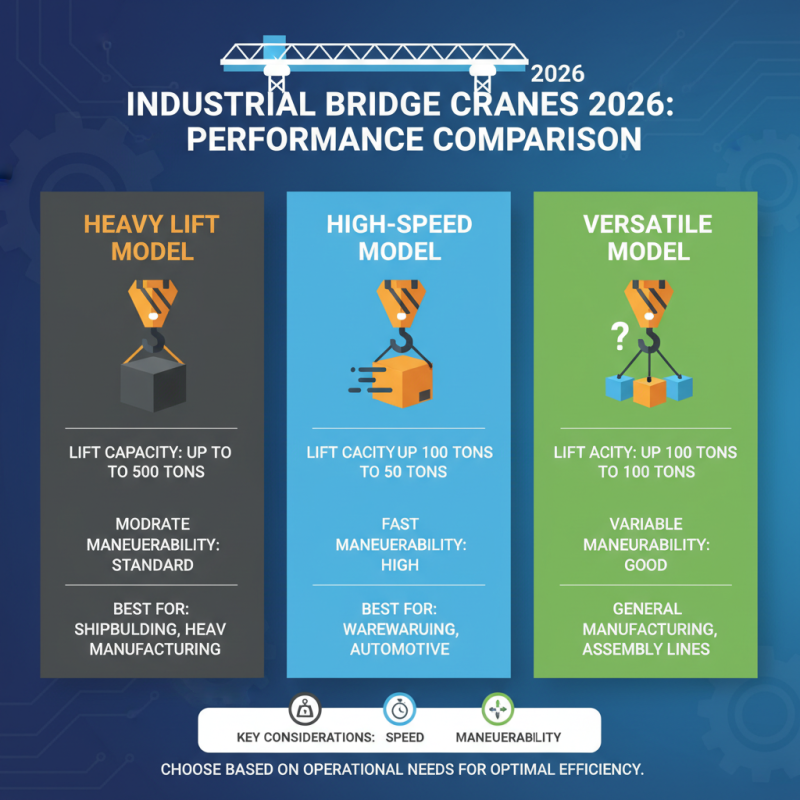

When exploring the best bridge crane models for industrial applications in 2026, performance comparison is essential. Different models exhibit varying lift capacities and operational speeds. Some may excel in maneuverability but lack in lifting power. This discrepancy can impact operational efficiency significantly.

One specific model may boast a high lifting capacity, yet struggle with stability. Another could be efficient in tight spaces but not suitable for heavy loads. Such factors should not be ignored. Analyzing user feedback often reveals hidden flaws that manufacturers won’t disclose.

Invest time in understanding the performance metrics. Evaluate how different environments affect these cranes. For instance, outdoor usage may expose weaknesses such as weather resistance. Ultimately, assessing these models requires a nuanced approach to performance details, rather than a mere focus on specifications.

As we look towards the future of bridge crane technology, several trends are emerging. Automation is at the forefront. Many industries are exploring how robotics can enhance efficiency and safety. Smart sensors play a crucial role. They can detect load weight and optimize lifting operations in real-time. This reduces the risk of errors, making operations smoother.

Another trend is sustainability. Industries are now focusing on using eco-friendly materials and energy-efficient designs in bridge cranes. This shift could significantly reduce the carbon footprint of heavy lifting operations. Moreover, the integration of renewable energy sources, such as solar, is becoming more common. This may not only save costs but also align with environmental goals.

Tips: When considering new technologies, evaluate your specific needs. Not all innovations will suit every application. Assess the safety features—ensuring they meet industry standards is essential. Lastly, keep an eye on maintenance; more advanced machinery may require specialized training for operators. Reflect on past experiences; mistakes can guide future investments.

| Model | Load Capacity (tons) | Span (meters) | Features | Future Trends |

|---|---|---|---|---|

| Model A | 10 | 15 | Smart controls, Low energy consumption | Automation integration, AI monitoring |

| Model B | 20 | 18 | Enhanced safety systems, High efficiency | Sustainable materials, IoT connectivity |

| Model C | 25 | 20 | Modular design, Remote operation | Predictive maintenance, VR training |

| Model D | 30 | 22 | Fast operation speed, Energy recovery systems | Remote diagnostics, Edge computing |