Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

The landscape of heavy lifting solutions is evolving rapidly, particularly with the increasing reliance on Girder Cranes in various industries such as construction, manufacturing, and logistics. According to a recent report by MarketsandMarkets, the global crane market is projected to reach USD 50 billion by 2025, with a compound annual growth rate (CAGR) of 5.5%. This growth is driven by the ever-increasing need for efficient lifting solutions capable of handling significant loads safely and effectively.

Girder Cranes, known for their robust design and superior load capacity, play a crucial role in meeting the demands of modern heavy lifting operations. With advancements in technology, the integration of IoT and automation into crane systems is expected to enhance operational efficiency, reduce downtime, and improve safety standards. For instance, a study by ResearchAndMarkets highlights that automated lifting solutions can reduce labor costs by up to 30%, while also decreasing accident rates in workplaces.

As industries continue to seek innovative solutions for heavy lifting, it is imperative to examine the top trends influencing the development and implementation of Girder Cranes. This exploration will not only shed light on the features and functionalities shaping the future of lifting solutions but also underscore the importance of safety, efficiency, and technological integration in optimizing crane operations.

The lifting industry is witnessing a transformative shift with the integration of emerging technologies in girder cranes. Recent industry reports indicate that the global market for crane technology is expected to reach USD 35 billion by 2025, driven largely by advancements in smart technology and automation. These innovations not only enhance the lifting capacity of girder cranes but also improve operational efficiency and safety. For instance, the implementation of IoT (Internet of Things) sensors allows real-time monitoring of load weights and equipment performance, leading to predictive maintenance. This reduces downtime and operating costs, enabling industries to maximize productivity during heavy lifting tasks.

Moreover, the advancement of lightweight yet durable materials in crane construction has significantly elevated their capacity. A study by the International Association of Crane Operators noted that cranes developed with high-strength steel and advanced composites can handle loads exceeding 20% more than traditional models. As regulatory standards evolve to accommodate these innovations, industries including construction, shipping, and manufacturing are increasingly adopting these advanced girder cranes to stay competitive in a fast-paced market. With a focus on sustainability, many manufacturers are also exploring electric and hybrid crane models, promoting eco-friendly operations while retaining high lifting capabilities.

The heavy lifting industry is undergoing a significant transformation as sustainability becomes a paramount concern for manufacturers and operators of girder cranes. By 2025, data from industry reports indicate that around 60% of companies are expected to adopt eco-friendly practices in their operations, driven by both regulatory pressure and market demand. A shift towards electric cranes, for instance, demonstrates a commitment to reducing carbon footprints, with electric solutions noted for generating up to 30% less emissions compared to traditional diesel-powered models. This trend reflects a broader movement within the industry to prioritize environmental stewardship while maintaining productivity.

Moreover, the integration of advanced technologies such as IoT and AI is paving the way for smarter, more efficient lifting solutions that are also sustainable. Predictive maintenance tools, fueled by AI algorithms, can reduce energy consumption by optimizing operational efficiency, leading to a decrease in resource waste. It is projected that by 2025, companies investing in these technologies will experience up to a 25% reduction in operational costs, further underlining the long-term financial benefits of sustainable practices. With an increasing focus on lifecycle assessments, the industry is poised to not only meet but exceed sustainability benchmarks, positioning heavy lifting solutions as key players in the global movement towards greener operations.

In 2025, the emphasis on safety innovations in girder crane design and operation is set to redefine heavy lifting solutions.

As industries increasingly prioritize worker safety, advancements in technology are pivotal. According to a report by the Global Association of Heavy Equipment Manufacturers, approximately 50% of crane-related accidents are due to operational errors. Thus, incorporating smart technology into crane systems, such as real-time monitoring and automated load management, can significantly reduce human error and enhance safety compliance.

The integration of advanced sensors and AI-driven analytics is expected to elevate operational safety standards.

These systems can provide operators with immediate feedback on load stability, environmental conditions, and potential hazards, effectively minimizing risks. A recent study indicates that cranes equipped with such technologies can reduce incident rates by up to 30%. Moreover, innovations in communication protocols, including wireless connectivity between cranes and control systems, foster seamless operations, allowing for timely interventions when safety parameters are breached.

As the girder crane industry moves towards these high-tech solutions, safety will undoubtedly become a cornerstone in the evolution of heavy lifting operations.

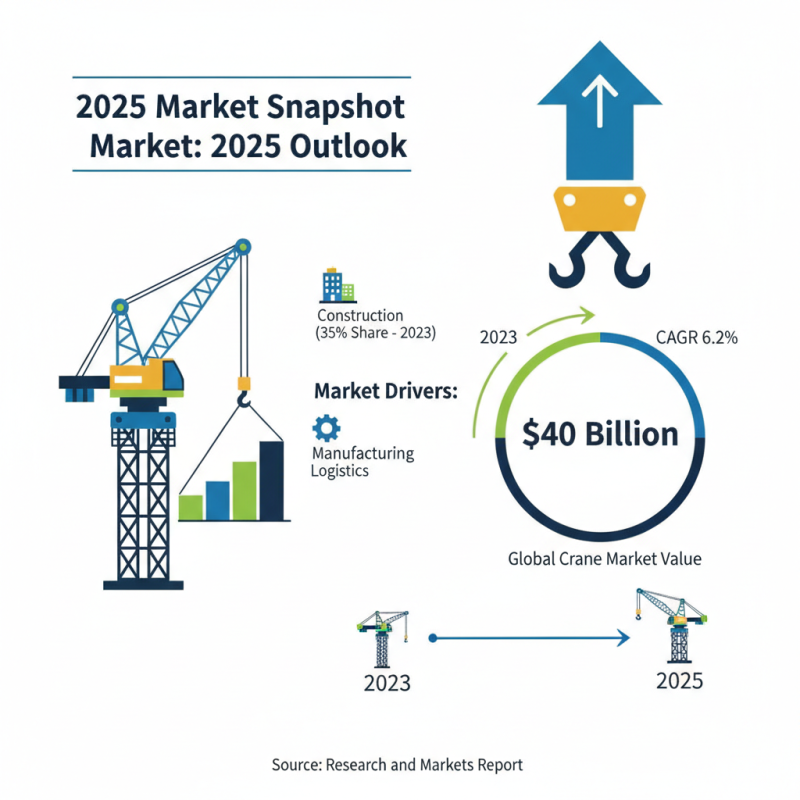

As we advance towards 2025, the heavy lifting crane market is witnessing significant evolution driven by various industries. According to a recent market research report by Research and Markets, the global crane market is expected to reach approximately $40 billion by 2025, growing at a CAGR of 6.2%. This surge is largely fueled by the booming construction, manufacturing, and logistics sectors. For instance, the construction industry alone accounted for over 35% of the market share in 2023, highlighting its critical role in driving demand for heavy lifting solutions.

Innovative technologies, such as IoT-enabled cranes and automation, are reshaping the landscape of heavy lifting. The increasing need for efficiency and safety in operations is pushing manufacturers to adopt smart technology, which has led to a 20% reduction in operational downtime reported by several leading firms. Industries are opting for eco-friendly cranes to meet sustainability goals, responding to growing environmental regulations and corporate social responsibility initiatives.

Tips: When selecting a heavy lifting crane, consider the specific needs of your operation, including load capacity and height requirements. Conduct regular maintenance to enhance operational efficiency and extend equipment lifespan. Additionally, ensure that your lifting solutions are compliant with the latest industry standards to maximize safety in the workplace.

As the construction and manufacturing industries continue to evolve, balancing performance and affordability in heavy lifting solutions remains paramount in 2025. The introduction of advanced materials and technologies has driven innovation in girder cranes, enabling stronger, lighter designs that can handle increased loads without compromising on cost. Manufacturers are increasingly focusing on creating cost-effective solutions through efficient production methods and streamlined supply chains. This not only reduces the overall investment for companies but also ensures that high-performance machinery is accessible to a wider range of businesses, from small enterprises to large-scale operations.

Moreover, the emphasis on sustainability is driving the development of cranes that utilize energy-efficient motors and regenerative braking systems. These advancements not only enhance the performance of heavy lifting equipment but also significantly lower operating costs, making them more appealing to businesses looking to optimize their resource allocation. In 2025, the integration of smart technology into girder cranes plays a vital role in achieving cost-effectiveness. Real-time data analytics and predictive maintenance capabilities improve efficiency and reduce downtime, allowing organizations to get the most value from their investments. As various industries demand effective and affordable heavy lifting solutions, the ideal combination of technological advancements and cost control strategies is set to define the future of girder cranes.