Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

In the ever-evolving landscape of material handling and logistics, the realm of ceiling cranes is witnessing remarkable innovations that promise to redefine efficiency and safety standards. According to Dr. Emily Hart, a noted expert in the ceiling crane industry, "The future of ceiling cranes lies in integrating advanced technology with ergonomic designs to enhance user experience and operational performance." As we approach 2025, this sentiment reflects the industry's commitment to adapting to new challenges and demands.

The advancements in ceiling crane technology are not just about enhanced lifting capacities or automated controls; they encompass a broader vision of sustainability and worker-centered design. With features such as real-time monitoring systems and improved safety mechanisms, ceiling cranes are becoming indispensable tools in various sectors, from manufacturing to construction. By analyzing current trends and innovations, it becomes clear that adaptability and smart technology will play pivotal roles in shaping the future of ceiling cranes.

As we delve into the emerging trends and innovations set to dominate the ceiling crane industry by 2025, it is crucial to consider the implications for businesses and workers alike. The intersection of technology and human factors will determine the trajectory of this essential equipment, ensuring that ceiling cranes not only meet the demands of today but also pave the way for a more efficient and safe operational environment in the years to come.

In 2025, the ceiling crane industry is poised for significant advancements driven by emerging technologies that aim to enhance efficiency, safety, and versatility. One notable trend is the integration of artificial intelligence (AI) and machine learning in crane operation systems. According to a recent industry report, over 40% of crane manufacturers are expected to adopt AI-powered solutions by 2025, allowing for real-time data analysis and predictive maintenance. This adoption not only minimizes downtime but also improves operational efficiency by optimizing load management and reducing operational costs.

Another transformative development is the incorporation of IoT (Internet of Things) technologies in ceiling cranes. With an estimated 30 billion connected devices projected by 2025, cranes equipped with IoT sensors can facilitate remote monitoring and control. This innovation allows operators to track performance metrics and receive alerts on potential failures before they occur. Furthermore, it enhances collaboration between machines and workers on the ground, leading to more streamlined operations.

Lastly, sustainability is becoming a key focus in ceiling crane design, with an increasing push towards electric and hybrid models. A report from the International Energy Agency anticipates that electric cranes could reduce energy consumption by up to 50% compared to traditional diesel-powered cranes. As environmental regulations become more stringent, the shift toward greener alternatives not only meets sustainability goals but also appeals to a growing market demanding energy-efficient solutions.

| Innovation/Trend | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| Smart Technology Integration | Using IoT for real-time monitoring and performance analysis. | Increased efficiency and reduced downtime. | 2025 |

| Enhanced Safety Features | Incorporation of AI and machine learning to predict failures. | Improved worker safety and compliance with regulations. | 2025 |

| Eco-friendly Materials | Use of sustainable materials in crane construction. | Reduced environmental footprint. | 2025 |

| Telematics and Big Data | Utilization of big data analytics for operational insights. | Better decision making and operational efficiency. | 2025 |

| Modular Design | Crane systems that allow easy upgrades or expansions. | Flexibility and cost-effectiveness in scaling up operations. | 2025 |

As the demand for sustainable practices continues to rise, the ceiling crane manufacturing industry is adapting to incorporate eco-friendly innovations. According to a recent report from the Global Crane Market Analysis, the segment focusing on sustainability is expected to grow by 20% over the next five years. This shift is largely driven by the increasing regulatory pressures and the industry’s responsibility to reduce its carbon footprint. Manufacturers are investing in the development of cranes that utilize lightweight materials, which not only improve energy efficiency but also enhance load capacities while minimizing the use of materials.

Innovative technologies such as electric and hybrid drive systems are also gaining traction in the ceiling crane sector. Research from the International Energy Agency indicates that electric cranes reduce energy consumption by up to 30%, significantly cutting operational costs and CO2 emissions. Furthermore, recyclable materials and responsible sourcing practices are becoming standard, as manufacturers strive to meet eco-certifications that appeal to environmentally conscious clients. This shift towards sustainability is not just a trend; it's a crucial step toward the future of the industry, promising a cleaner, more efficient operational landscape.

This chart illustrates the influence levels of various key trends impacting ceiling crane manufacturing in 2025, with a particular emphasis on sustainability practices, automation advancements, safety enhancements, and the integration of smart technologies.

The advancements in safety features for ceiling cranes are pivotal as industries continue to prioritize worker safety and operational efficiency. A 2023 report from the International Crane Safety Council reveals that enhanced safety protocols have significantly reduced crane-related accidents by approximately 30% over the last five years. Modern ceiling cranes now incorporate state-of-the-art safety mechanisms, including overload detection systems, automatic emergency stops, and enhanced operator visibility through improved control interfaces. These innovations not only mitigate the risk of accidents but also foster a safer working environment, resulting in increased productivity.

Moreover, the integration of smart technology plays an essential role in elevating the safety standards of ceiling cranes. Recent findings from the Global Construction Equipment Market Analysis indicate that the adoption of IoT-equipped cranes has surged by 25% in the past two years. This technology allows for real-time monitoring of crane performance and conditions, enabling prompt identification of potential hazards. As a result, operators are empowered to make informed decisions quickly, significantly reducing the likelihood of accidents. Enhanced training programs, coupled with these technological advancements, ensure that personnel are well-prepared to handle the complexities of modern ceiling crane operations safely.

The market for ceiling cranes is anticipated to witness significant growth by 2025, driven by increasing demand across various industries such as construction, manufacturing, and logistics. According to a recent industry report, the global ceiling crane market is expected to grow at a compound annual growth rate (CAGR) of 6.5%, reaching a valuation of approximately $2.4 billion by 2025. This surge is attributed to the rising need for efficient material handling solutions and the growing emphasis on workplace safety, as ceiling cranes offer a reliable way to lift and transport heavy loads.

One notable trend is the integration of advanced technologies such as IoT and AI in ceiling crane systems. These innovations enable real-time monitoring and predictive maintenance, significantly enhancing operational efficiency. For example, cranes equipped with smart sensors can provide data analytics on performance, allowing businesses to optimize their workflow and reduce downtime. As companies look to streamline their operations, the demand for advanced ceiling crane systems will only continue to grow.

Tips: Businesses should assess their specific lifting needs and evaluate how modern crane technologies can be integrated into their operations. Investing in training for staff on new systems and safety protocols will further leverage the benefits of ceiling cranes. Additionally, maintaining compliance with industry regulations can enhance safety and operational efficiency in the workplace.

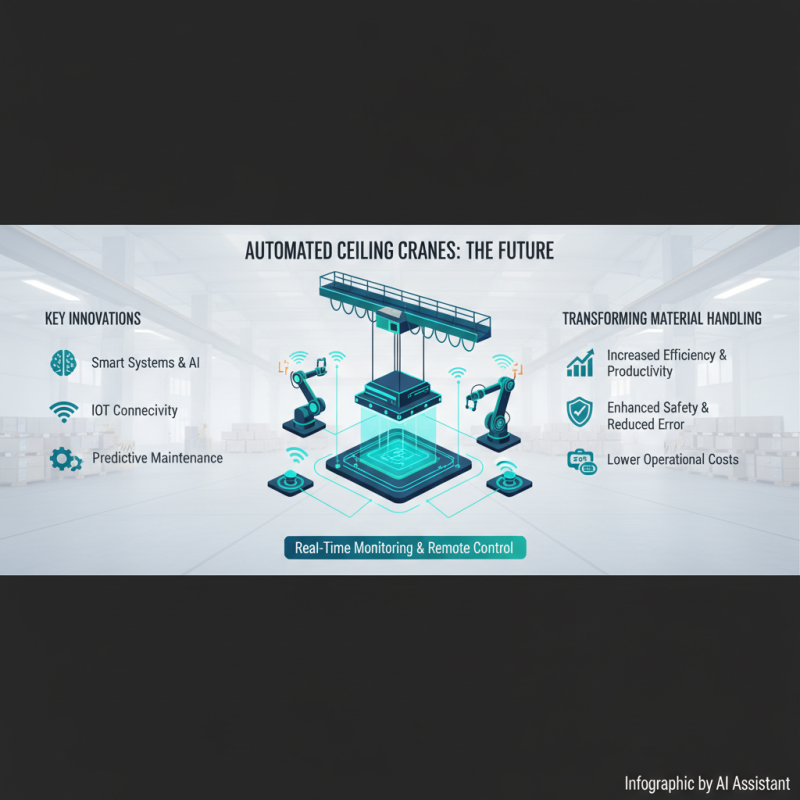

The future of automation in ceiling cranes is set to transform the material handling industry significantly. As industries seek to enhance efficiency and reduce operational costs, the integration of smart systems into ceiling cranes has become a focal point of innovation. These advancements enable real-time monitoring and control, allowing operators to manage crane systems remotely and thereby increase productivity while minimizing human error. Smart sensors and IoT connectivity are at the forefront, facilitating predictive maintenance and ensuring safety protocols are maintained without constant manual oversight.

Moreover, the advent of artificial intelligence in crane operations is revolutionizing how materials are lifted and transported. AI algorithms can analyze operational data to optimize lifting processes, reduce energy consumption, and even simulate workflows for improved planning. This shift towards smarter, automated ceiling cranes not only enhances operational capabilities but also contributes to a safer working environment. By leveraging technology, industries can expect improved reliability and versatility in their material handling solutions, marking a significant step forward in the development of automated systems.